What is a Compression Spring?

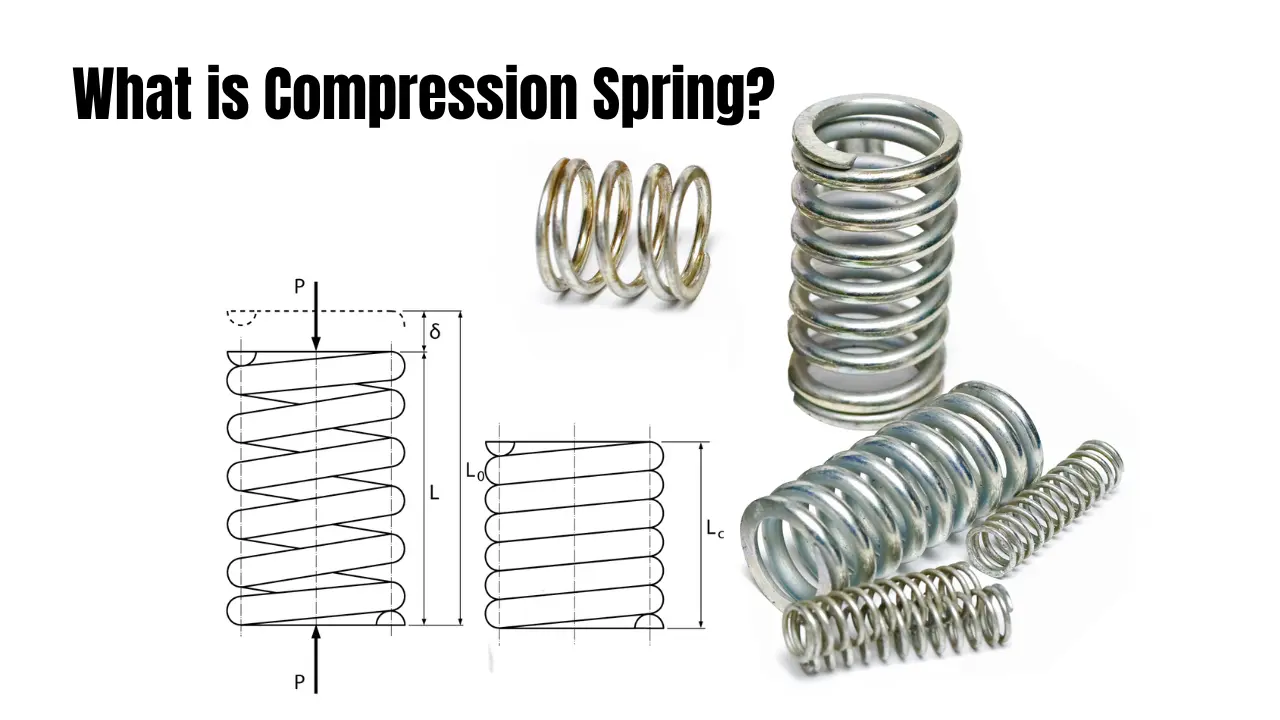

A compression spring is an open-coil helical spring that offers resistance to a compressive force applied axially. They are usually coiled at a constant diameter, though they can be coiled in other needed forms such as conical, concave (barrel), convex (hourglass), or various combinations of these.

Compression springs are used to resist force and/or store energy, depending upon the application.

Compression springs apply a force by compressing or pushing on them. Compression springs are all cylindrical and made out of round stainless steel or music wire.

Compression springs can also be made in many shapes including barrel, conical, hourglass, or oval. The wire can also be square, rectangular, or virtually any shape, size, or material.

By far the most widely used type of spring, compression springs are designed to oppose compression and return to their uncompressed length when the applied force is removed. The potential applications for compression springs are limited only by the imagination.

Compression Spring Dimensions

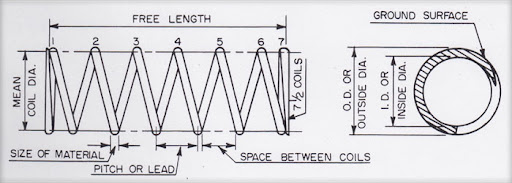

To measure a compression spring, you can use dial calipers, a micrometer, a ruler, or a tape measure for larger springs. When measuring a compression spring, you must determine the following five elements:

- Outer diameter is measured by placing your dial calipers on the outside of the coil’s width.

- Inner diameter is defined as the width of the inside of a coil spring’s diameter measured from the center of the helix. Sometimes, inner diameter can be difficult to measure accurately. The formula to calculate inner diameter is I.D. = O.D. – 2d where 2d is two wire diameters.

- Defined as the full length of an uncompressed spring, free length is easy to find. To measure, place your calipers on the full length of the spring.

- Wire diameter is found by placing your calipers on the wire in the center of your spring.

- Total coil count is defined as each full rotation and the remainder of the last coil.

How to Measure a Compression Spring

- Measure the spring wire diameter, preferably to 3 decimal places for accuracy using calipers.

- Measure the outside diameter of the coils. This might vary slightly from coil to coil, take the larger value measured.

- Measure the length in its free condition (uncompressed).

- Count the number of coils. This is also the number of revolutions going from tip-to-tip; count to the closest 1/8th.

- Note the winding direction of the coils. In most applications this is not important but review surrounding parts whether they require the spring to be in a specific direction.

- Note the end type of the spring. Compression springs may have the ends ground or not ground, the end coils may be open or closed, or some other configuration that may require a blueprint description.

- Determine the spring wire material type. If the wire is not attracted to a magnet, then it might be a special metal alloy that needs exact identification. If the material is unknown, then take note of any extreme operating conditions such as: very high or low temperatures, presence of corrosive materials or rapid cycling.

Service Life

It should be noted that if critical force versus deflection linearity is required, only the middle 60-80% of the available deflection range should be used.

Therefore, reserve at least the first and last 15-20% of the area for possible spring end and adjacent coil contact effects. These effects can largely be neglected in most spring applications.

This can be achieved if the spring in question is not exposed to shock loads, rapid cycles, extreme temperatures, corrosion, or stress values above the recommended values.

If the spring is statically loaded (not cyclically), almost infinite service life can be expected. A longer spring life can be achieved by shot peening.

Materials

Examples of compression springs in different metals In the manufacture of springs, spring wire of the highest quality is used.

The term “spring steel” is an inventory term that includes musical wire, hard drawn (MB) wire, and oil-hardened wire. Additionally, standard compression spring materials can include stainless steel (300 series), beryllium copper, and phosphor bronze.

Tolerances

Calculated rates and loads based on geometric SMI tolerances are approximate +/- 10%. Low or high index feathers have higher scores.

Compression springs typically have an hourglass shape when wound on an automatic winder; Therefore the outside / inside tolerance is only applied to the end coils. This is an improvement consideration when choosing a spring that will fit over a rod or inside a cylinder.

FAQs

What is a compression spring?

Compression Springs are open-coil helical springs wound or constructed to oppose compression along the axis of wind. Helical Compression is the most common metal spring configuration. These coil springs can work independently, though often assembled over a guide rod or fitted inside a hole.

What does a compressed spring do?

A compressed spring is a type of spring that produces linear force. The force is produced when a weight is applied to either the top or bottom of the spring. There are many variations of a compressed spring such a conical compressed spring, variable pitch compressed spring, and barrel compressed spring.

How strong are compression springs?

The amount of force that a compression spring can resist – in other words, the overall strength, stiffness, or spring rate of a given product – depends on various metrics and specifications. These include its physical design, material strength, and manufacturing methods.

What is the difference between a pressure spring and a compression spring?

Although a tension and compression spring are both helical coiled springs, the difference in their functionality and purpose can be significant. In essence, tension springs are designed to bring components together, whilst compression springs are made to keep components apart.

What are the disadvantages of compression springs?

In conclusion, compression springs offer many benefits but also have some disadvantages that must be considered. These disadvantages include a limited lifespan, susceptibility to buckling, a limited range of motion, additional components requirement, and customization difficulty.

What are the benefits of compression spring?

Compression springs offer resistance to linear compressing forces (push), and are in fact one of the most efficient energy storage devices available. The amount of energy stored in a compression spring is determined by the spring’s material properties, wire diameter, and number of coils.