What is Hammer?

A hammer is a tool, most often a hand tool, consisting of a weighted “head” fixed to a long handle that is swung to deliver an impact to a small area of an object. This can be, for example, to drive nails into wood, to shape metal, or to crush rock.

Hammers are used for a wide range of driving, shaping, breaking, and non-destructive striking applications. Traditional disciplines include carpentry, blacksmithing, warfare, and percussive musicianship.

Hammering is the use of a hammer in its strike capacity, as opposed to prying with a secondary claw or grappling with a secondary hook.

Carpentry and blacksmithing hammers are generally wielded from a stationary stance against a stationary target as gripped and propelled with one arm, in a lengthy downward planar arc downward to add kinetic energy to the impact.

Pivoting mainly around the shoulder and elbow, with a small but brisk wrist rotation shortly before impact.

For extreme impact, concurrent motions of the torso and knee can lower the shoulder joint during the swing to further increase the length of the swing arc (but this is tiring).

War hammers are often wielded in non-vertical planes of motion, with a far greater share of energy input provided from the legs and hips, which can also include a lunging motion, especially against moving targets.

How To Use A Hammer?

Many injuries are caused by a lack of simple know-how when it comes to hammer use. Indeed, nearly 120,000 injuries occur each year in the U.S. due to improper workshop manual tool use, and experts estimate that about 30,000 of these are due to hammer accidents specifically.

Here are some general best practices for hammer use:

Before getting started using a hammer, ensure it is suitable for work. If the tool has obvious signs of degradation, such as a loosehead, patches of rust, or splintering wood, do not continue to use it — it may break on impact and cause injuries.

Be sure to invest in some safe eyewear. While it may seem unlikely, it’s not uncommon for nails or other objects to fly toward you while you are hammering.

When you are using a hammer, stay absolutely focused on the task at hand. Multitasking is off-limits. If you become distracted during work, you may cause damage to property or to yourself.

Let’s discuss how you should swing a hammer. First, look over your shoulder to ensure that no person or object will be endangered when you start working.

Next, wrap your hand around the grip of the hammer, positioning your thumb on top of it; this gives you greater control over your swings.

Keep a firm grip on the tool so that it will not fly out of your hand, then line up the hammer with the item you’re hitting.

Start with a gentle tap, then increase your power once the item is set in place. You should be able to drive the item with moderate force.

Our line of hammers features a ballistically balanced design for maximum striking power and a bi-material shock-absorbing grip for ultimate control and vibration reduction to help lessen the impact on joints over time.

Note that how you swing your hammer will vary slightly from type to type, but these are some general concepts that you should remember, regardless of which hammer you’re using.

Types of Hammers

A wide range of Hammers are available, varying in shape, size, and weight. The different styles reflect different uses. Around the house, the average diy’er only really needs one or two types.

The shape of Hammerheads has not changed much over the years although some modern materials are now used in both the head and handle.

Traditionally handle was made of wood fixed through a hole in the head; this allowed the handle to be easily replaced if required.

Modern hammers use modern materials and the handles are often built into the head – often with a form of built-in shock absorber to make them easier to use.

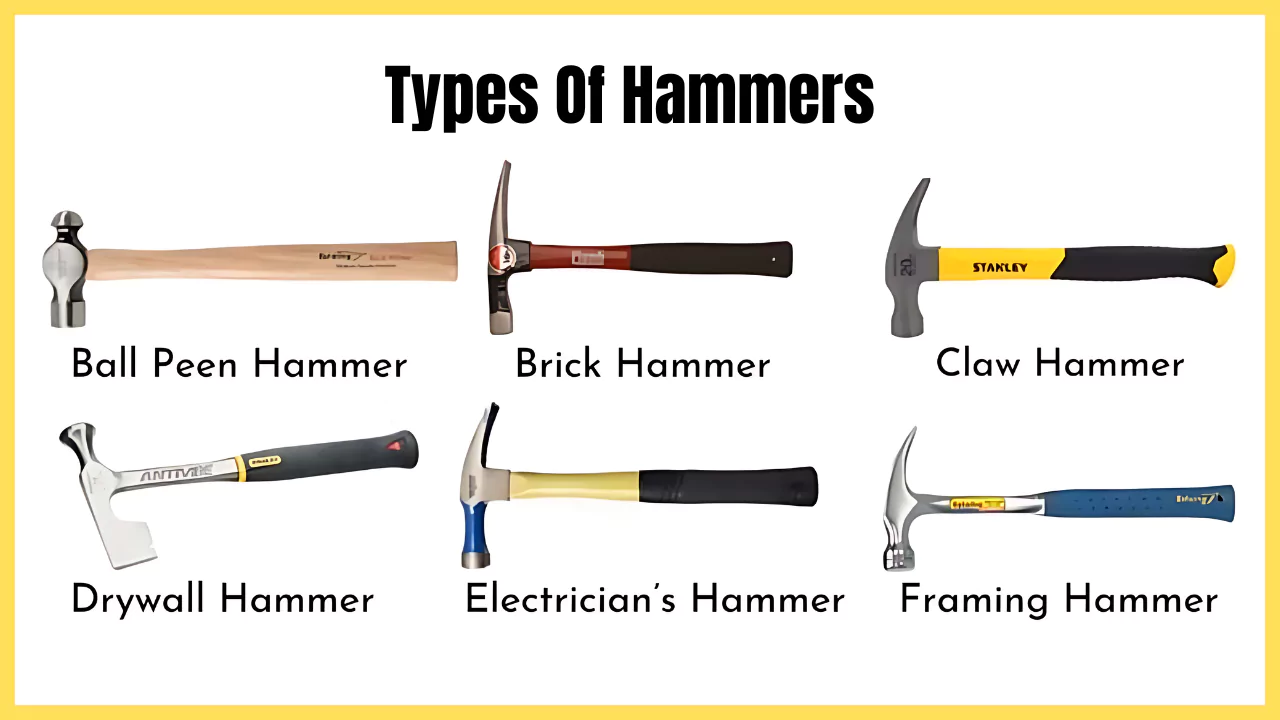

List of The Most Common Types of Hammers and Their Purpose:

- Ball Peen Hammer

- Brick Hammer

- Claw Hammer

- Drywall Hammer

- Electrician Hammer

- Framing Hammer

- Sledgehammer

- Tack Hammer

- Trim Hammer

- Cross and Straight Pein

- Cross Pein Pin Hammer

- Club Hammer

- Joiner’s Mallet

- Soft-faced Hammers

- Scaling Hammer

- Powered Nailers Hammer

- Dead Blow Hammer

- Blacksmith Hammer

- Blocking Hammer

- Brass Hammer

- Bushing Hammer

- Chasing Hammer

- Hatchet Hammer

- Rock Hammer

- Scutch Hammer

#1. Ball Peen Hammer.

Also known as a machinist’s hammer, a ball-peen hammer is identifiable by its two heads: around one and a flat one.

Though this tool is traditionally used in metalworking, it can also be used to strike punches and chisels, as well as round off edges on rivets.

Normally used by engineers, the pein in this case, is rounded and is usually used for shaping metal and closing rivets.

Ball pein hammers are available from 55 – 1100 (4 oz up to 2 lb.), 110 – 165g (8oz 12oz) are the most suitable for general use. Handles are normally wood, usually Ash or Hickory.

#2. Brick Hammer.

A brick hammer often referred to as a stonemason’s hammer has a flat face with a distinctive chisel-like blade on the other end.

As the name suggests, this tool can be used to break off pieces of brick, stone, or concrete. Brick hammers are often made with high-grade steel heads and fiberglass or hardwood handles.

#3. Claw Hammer.

The most popular hammer for general work, available with a wooden (often hickory), glass-fiber, or steel handle; with or without a rubber grip.

The most popular weights are 455-680g (16 to 24oz). The claw is normally curved and incorporates a ‘V’ cut-out to draw nails from timber.

The claw can be used to lever up floorboards or where other places where a lever is required; care must be taken (especially with cheaper models) as the force applied can easily weaken the joint between the handle and the head.

Some claw-nailing hammers will have a waffle-faced head, while others will have a smooth one, such as our 20-ounce smooth-face nailing hammer.

The former is useful for increased accuracy, but it can leave an imprint of your hammer on the surface; a smooth driving face will generally not do this.

#4. Drywall Hammer.

This straight peen hammer has a very specialized end that more closely resembles a hatchet with a notch in the bottom.

The notch is used for holding nails in place without damaging the drywall paper, and the blade of the pein can be used to chop off excess bits of drywall safely.

#5. Electrician Hammer.

An electrician’s hammer looks and handles nearly identical to a claw hammer. However, it is constructed with an insulated fiberglass handle and a rubber-coated grip, which allows it to be used for electrical work. It also has a longer striking face, which helps contractors do work in tight areas.

This variation of a claw hammer has an extended neck on the head. This allows electricians to target nails embedded in hard-to-reach places.

#6. Framing Hammer.

This is a specialty claw hammer that is about twice as heavy as a standard claw hammer. While a standard claw hammer weighs up to 16 ounces, a framing hammer can weigh up to 32.

Our milled face framing hammer weighs in around the middle, at 22 ounces. This weight, along with its waffled striking surface, allows contractors to drive nails quickly without them slipping.

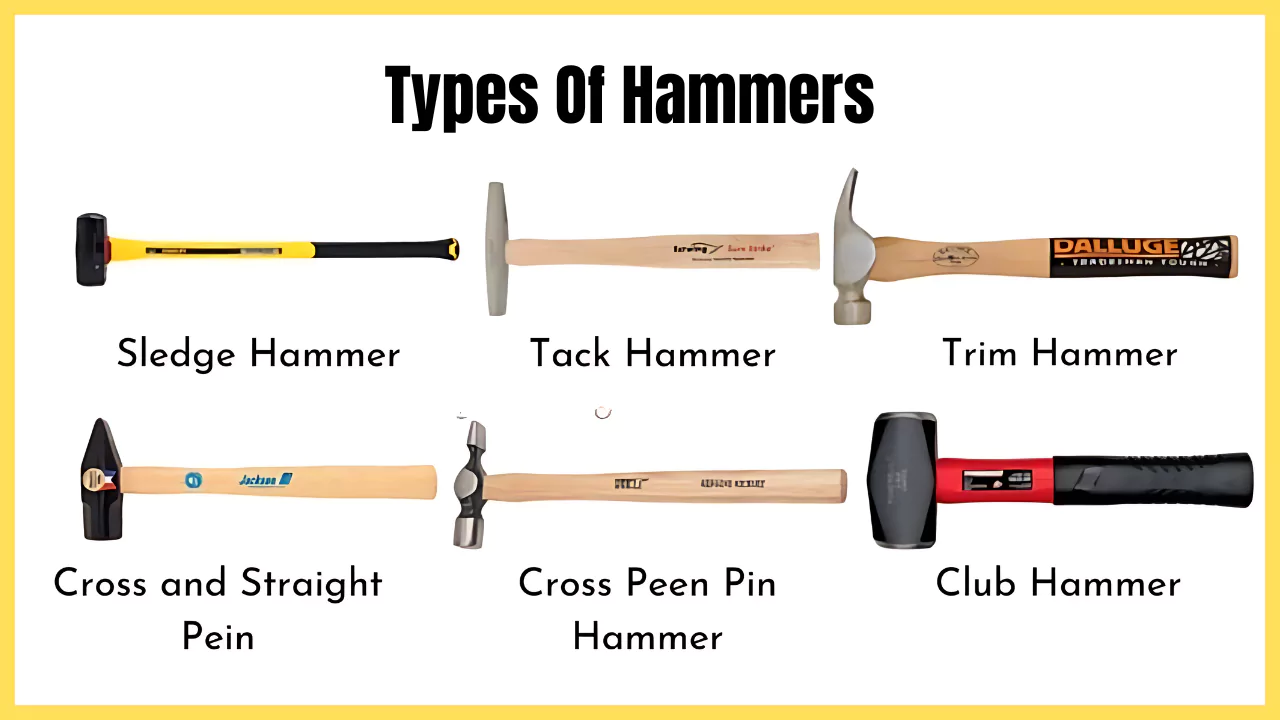

#7. Sledgehammer.

Used for the heavier jobs, such as driving in stakes or to break up concrete, stone or masonry. For lighter jobs, just the weight of the head may be used for blows, but for heavier work, the hammer is swung like an ax. Wear suitable protective clothing, including safety glasses. Weights 7, 10, and 14 lb.

#8. Tack Hammer.

Also known as an upholstery hammer, a tack hammer is a lightweight tool for driving upholstery into furniture or surfaces. Most tack hammers have two faces, with the split side being magnetized to help users place tacks accurately.

#9. Trim Hammer.

Similar in size and weight to a tack hammer, a trim hammer is simply a small, straight claw hammer that can be used to drive trim nails without damaging anything in the work area.

#10. Cross and Straight Pein.

Again, mainly used for shaping metal, the pein can be at right angles to the handle or parallel with it. The most useful domestically is the cross pein, where the pein can be used for starting panel pins and tacks. Handles are normally wood, usually Ash.

The wedge-like pein of this hammer is horizontally aligned. It can be used for starting panel pins or tacks without the risk of hitting your fingers. It is also used for shaping metal.

#11. Cross Pein Pin Hammer.

A lighter version of the Cross and Straight Pein hammer, ideal for light joinery and cabinet work. Weight 55g (4oz).

A lighter variation of the cross-peen hammer, this tool isn’t well-suited for metalwork. Instead, it’s most useful in cabinetwork, light joinery, and other woodworking tasks,

#12. Club Hammer.

Sometimes called a Lump Hammer, it has a double-faced head, and is useful for light demolition work, driving steel chisels, and masonry nails.

As debris is likely to fly, the wearing of safety glasses and work gloves is recommended. Weight 1135g (2 1/2 lb) being best suited to domestic work. Handles are normally wood, usually Hickory, or synthetic resin.

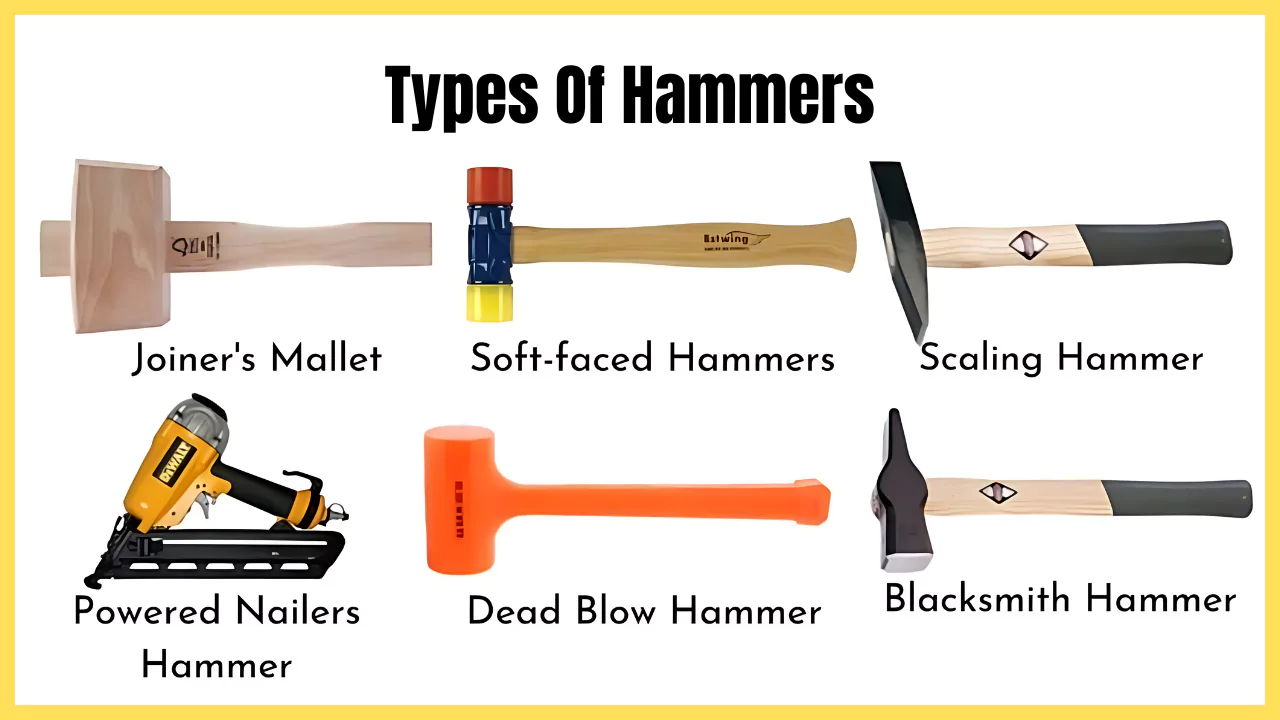

#13. Joiner’s Mallet.

Used to drive chisels or to tap wood joints together, where a metal-faced hammer would cause damage or bruising.

Note that the head is slightly tapered to ensure correct contact with the work. Both the handle and head are wood, usually Beech or Lignum Vitae.

#14. Soft-faced Hammers.

Various types are available, with hard and soft rubber, plastic or copper faces. Some come with a choice of faces that are interchangeable.

Useful for striking materials such as chrome wing outs, where a steel face would cause damage. In some cases, can replace a mallet for cabinetwork.

#15. Scaling Hammer.

Featuring a vertical chisel and pick instead of normal heads, these hammers are used for removing scale, rust, and various types of hard coating from boilers and other surfaces.

Pneumatic versions range from single-headed to triple-headed models and function more like a jackhammer.

#16. Powered Nailers Hammer.

These take the hard work out of fitting nails, staples, etc. They are ideal where a large number of nails need to be fitted, such as fixing floorboards.

They range from light-duty (for use when fixing edge moldings, picture frames, etc) to heavy-duty nailers, used to fix floorboards and garden decking, etc. May be powered by compressed air canisters or electricity.

#17. Dead Blow Hammer.

The head of this hammer is specially designed for minimal recoil and soft blows. It usually has either a solid rubber or plastic head or a semi-hollow head filled with sand or lead shot.

They can be used in everything from woodworking to automotive applications where they aid in dislodging parts, fixing small dents, and knocking wood together or apart without marring the surface.

#18. Blacksmith Hammer.

Unlike what is depicted in popular fantasy games, the blacksmith’s hammer is a type of sledgehammer where the second head is slightly tapered and rounded. It is designed specifically for shaping red-hot steel against an anvil.

#19. Blocking Hammer.

Featuring a flat, square head on one side and cylindrical head on the other, this is another hammer commonly used by blacksmiths. It can be used for shaping metal on a block or anvil.

#20. Brass Hammer.

Brass hammers have a thin, cylindrical double-head which is used for pounding steel pins without damaging the surrounding surface. It can be found in both automotive and woodworking shops.

#21. Bushing Hammer.

This unusual hammer resembles a meat tenderizer with an extended metalhead. It’s used to add a rough texture to stone, which may have an aesthetic purpose or make stone walkways less slippery.

#22. Chasing Hammer.

A very unusually shaped hammer, the chasing hammer has a bulbous-ended handle, rounded head, and small, round pein. It is used primarily for shaping metal jewelry.

#23. Hatchet Hammer.

One of the more unusual types of hammers, the hatchet hammer (sometimes referred to as a half-hatchet) has an axe blade instead of a peen. It can be used for a variety of tasks and is thus well-suited for survival and emergency toolkits.

#24. Rock Hammer.

Also referred to as a pick hammer, this small tool has a flat head and either a chisel or pick on the back. They are most commonly used in geology and historical excavation to break small rocks.

The chisel is used for a variety of tasks, including splitting soft rock, removing vegetation, and creating small holes.

The pick variant often called a geologist’s pick, is able to split harder stones. Bricklayers sometimes use rock hammers to break up old brickwork joints.

#25. Scutch Hammer.

Scutching is the process of removing old mortar from bricks and paving. The hammers used for this have either one head and a chisel-like slotted scutch comb holder or two scutch comb holders.

The holders can hold scutch combs which function like toothed chisels, or droves. Which is used for a job depends upon whether the user prefers a hammer or multiple scutching attachments.

Tips for using hammers

- Always use the right hammer for the job, it will make the job easier and avoid possible damage to the hammer/workpiece.

- Never hit nails with the side of a check or a hammerhead. The metal at these points is not hardened as the striking face and could be damaged.

- When assembling delicate work, use a piece of scrap wood between the workpiece and the head of the hammer. This will prevent damage to the workpiece.

- Use a nail punch to sink nails into the timber, again this will prevent damage to the workpiece. A nail punch has a flat end (or slightly, concave) to fit the nail head rather than the pointed end that other punches have.

- Where the handle is held in the hammerhead by steel wedges, check regularly to ensure the wedges are tight. The timber handle can shrink in dry conditions.

- If a timber handle does start to become loose, place the head in water overnight, the water will cause the handle to expand and tighten in the head.

- If a hammer tends to slip off nails, roughen the face of the head using a medium abrasive paper.

- Always wear safety glasses when driving masonry nails or breaking up concrete.

FAQs

What are 5 different types of hammers?

1. Claw Hammer.

2. Ball Peen Hammer.

3. Sledgehammer.

4. Rubber Mallet.

5. Tack Hammer.

What is bigger than a hammer?

Sledge hammers are larger than most hammers and feature a metal, mallet-like head. Heavier sledge hammers with longer handles are intended to be swung with both hands.

What is a large mallet called?

Beetle mallets, also called a persuader or commander, are large mallets with a wood or plastic head, with rounded ends about 15 to 18 inches (380 to 460 mm) in diameter, and a handle about 3 feet (0.91 m) long.

What are small hammers called?

Tack hammers are for jobs that require delicacy and precision. Often called a Swiss style mini hammer, the tack hammer features a small, flat head and a narrow pointed end. These small tools are most often used in the fields of cabinetry and upholstery, which use small nails and tacks, and require much less force.

What are the 6 types of hammers?

Here are six of the most popular hammer choices:

1. Claw Hammer.

2. Warrington Hammer / Joiner’s Hammers / Cross Pein Hammer.

3. Ball Pein Hammer / Engineer’s Hammer / Mechanic’s Hammer.

4. Club Hammer or Lump Hammer.

5. Sledge Hammer.

6. Mallet.

What are 4 different specialty hammers and their uses?

These include a Brick Hammer for striking a bolster or splitting bricks; Woodcarving Mallet, with rounded body; Veneer Hammer, for pressing and tapping veneers into place; Upholsterer’s hammer for driving tacks and nails in confined spaces, and Sprig Hammer, used by picture frame makers.