There are different types of threads found, and some main types of threads are parallel threads, including BSPP, UN/UNF, and metric parallel. The second type of thread is tapered threads in which metric tapered, BSPT, and NPT thread/NPTF thread are included. Let’s learn the difference between each one of them.

What is Screw Thread?

A screw thread, often shortened to thread, is a helical structure used to convert between rotational and linear movement or force. A screw thread is a ridge wrapped around a cylinder or cone in the form of a helix, with the former being called a straight thread and the latter called a tapered thread.

A screw thread is the essential feature of the screw as a simple machine and also as a threaded fastener. The mechanical advantage of a screw thread depends on its pitch, that is the linear path that the screw covers in one revolution.

In most applications, the pitch of a screw thread is chosen so that there is sufficient friction to prevent the linear motion from being converted into rotary motion, that is so the screw does not slip even with the application of a linear force, as long as there is no external torque.

This property is essential for the vast majority of its applications. Tightening the screw thread of a fastener is comparable to driving a wedge into a gap until it sticks through friction and slight elastic deformation.

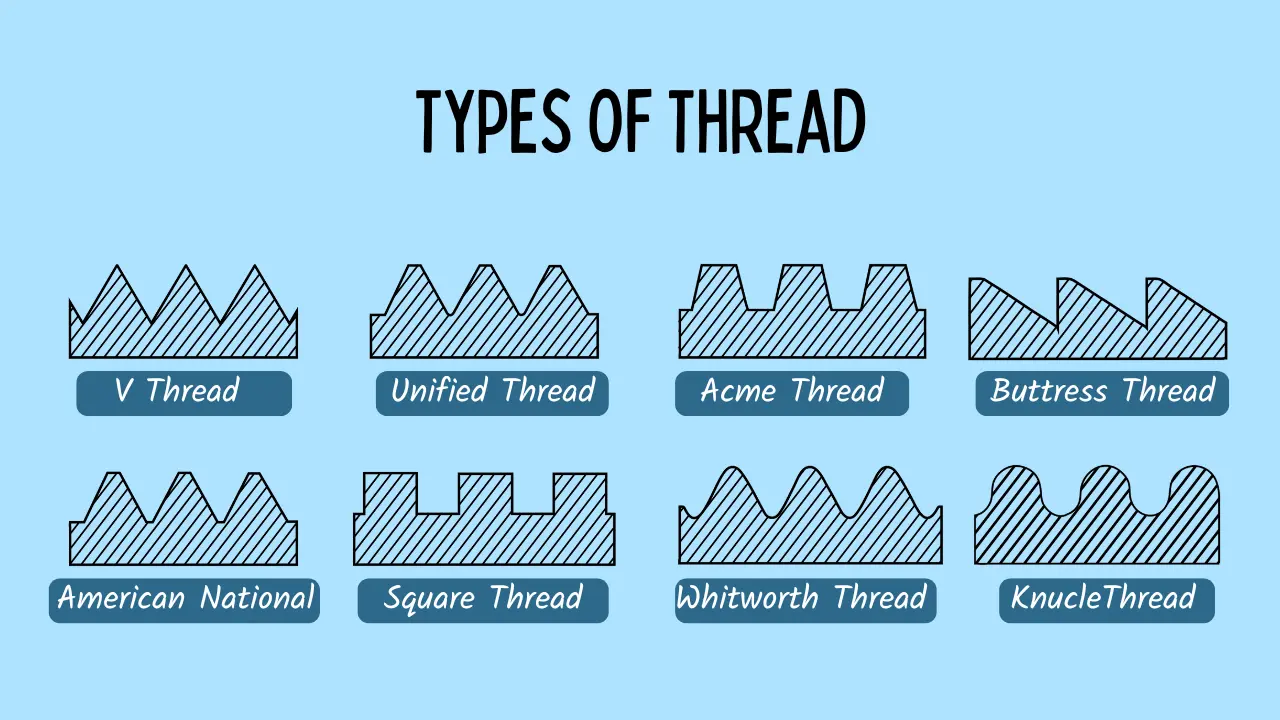

Types of Threads

Unified Thread Standard (UTS)

#1. Unified National Coarse (UNC)

UNC ( UNified National Coarse) are Unified coarse pitch threads. It is most commonly used in the USA. One of the key characteristics of this type of thread is It has a longer pitch, Greater tolerance that make them easier to assemble for the manufacturer.

The UNC thread has less teeth of the same length, larger cross-section size of each tooth, and more suitable for bearing larger tensile force and impact force. UNC threds are most commonly used in the mass production of the Screw, Bolts and nuts.

It has unique advantages in some rough operation applications that require quick assembly or disassembly and are easy to produce corrosion and damage.

#2. Unified National Fine (UNF)

UNF stands for “Unified Fine pitch thread” that is also one of the popular Thread in USA. UNF has a greater number of Thread per Distance than a Course Pitch Thread. And they are generally made from steel or stainless steel fasteners.

Since UNF Thread has a Fine threading they gives them a higher tensile strength, making them useful for machine part assembly and other high precision application.

UNF fixings are often used in the automotive and aerospace industries industry because of the requirement for tight, fine threads.

#3. Unified National Extra Fine (UNEF)

UNEF: Is the symbol for United extra fine pitch threads. This thread type is designed to be finer than UNF threads, UNEF threads are unique as they are used in specialized applications. These can include thin threaded walls and tapped holes in hard and thin materials.

Metric Thread

#4. Metric Coarse (M)

Metric course thread are just same as the UNC threads the only difference here is Metric course thread is measured using a metric unit that means Metric threads are measured in millimetres between each thread. For example, a thread labeled “M10” is considered coarse by default, while an “M10x1.25” thread is considered fine.

#5. Metric Fine (MF)

Metric fine threads are a fastners with a smaller pitch size and lower distance between Threads than a metric course Thread. Metric fine threads are also measured same as the metric course threads in millimetre.

Pitch size is usually specified along with the diameter and length of a metric fasteners. For example, an M10 x 1.25 thread has a fine pitch of 1.25 mm

Pipe Threads

#6. National Pipe Thread (NPT)

The thread type National Taper Pipe (NPT) is a tapered or conical pipe thread which is used for pipe fittings. The flank angle here is 60 degrees. Unlike NPTF, it is only self-sealing at low pressure.

NPT threads are a type of tapered thread commonly used in piping systems throughout North America.

The NPT thread has a unique design that helps ensure a tight seal and prevents leaks, making it a popular choice in many industries, such as plumbing, HVAC, and pharmaceutical manufacturing.

#7. National Taper Pipe Dryseal (NPTF)

The NPTF is a tapered or conical pipe thread, which is self-sealing and has a flank angle of 60 degrees. The main difference to the NPT thread is that the internal and external threads overlap and can therefore be self-sealing without the use of sealant.

#8. British Standard Pipe Thread (BSP)

The British Standard Pipe is a Whitworth pipe thread. It is a cylindrical thread and therefore not self-sealing. It is abbreviated with the abbreviation G. A small special feature is that the inch specification does not correspond to the inch diameter. For example: BSP 1″ = approx. 33.25 mm.

Machine Screw Threads

#9. American National Thread (AN)

The American national standard or U.S. or Seller’s thread has flat crests and roots. The flat crest can withstand more rough usage than sharp V-threads. These threads are used for general purposes e.g. on bolts, nuts, screws, and tapped holes.

#10. British Standard Whitworth (BSW)

British Standard Whitworth (B.S.W.) thread. This is a British standard thread profile and

has coarse pitches. It’s an asymmetrical V-thread in which the angle between the flanks, measured in an axial plane, is 55°.

These threads are found on bolts and screwed fastenings for special purposes. The various proportions of B.S.W.

The British standard threads with fine pitches (B.S.F.) were used where great strength at the root was required. These threads are also used for line adjustments and where the connected parts are subjected to increased vibrations as in aero and automobile work.

The British standard pipe (B.S.P.) threads with fine pitches are used for steel and iron pipes and tubes carrying fluids. In external pipe threading, the threads are specified by the bore of the pipe.

#11. British Standard Fine (BSF)

British Standard Fine (BSF) is a screw thread form, as a fine-pitch alternative to British Standard Whitworth (BSW) thread. It was used for steel bolts and nuts on much British machinery, including cars, prior to adoption of Unified, and later Metric, standards. For highly stressed conditions, especially in motorcycles, a finer thread, British Standard Cycle (BSC), was used as well.

Special Threads

#12. Acme Thread

It is a modification of the square thread. It is much stronger than square thread and can be easily produced. These threads are frequently used on screw-cutting lathes, brass valves, and bench vices.

When used in conjunction with a split nut, as on the lead screw of a lathe, the tapered sides of the thread facilitate ready engagement and disengagement of the halves of the nut when required.

#13. Buttress Thread

It is used for the transmission of power in one direction only. The force is transmitted almost parallel to the axis. This thread unit has the advantage of both square and V-threads.

It has a low frictional resistance characteristic of the square thread and has the same strength as that of a V-thread. The spindles of bench vices are usually provided with buttress threads.

#14. Square Thread

The square threads, because of their high efficiency, are widely used for the transmission of power in either direction. Such types of threads are usually found on the feed mechanisms of machine tools, valves, spindles, screw jacks, etc.

The square threads are not so strong as V-threads but they offer less frictional resistance to motion than Whitworth threads. The pitch of the square thread is often taken twice that of a B.S.W. thread of the same diameter.

Other Types

#15. Knuckle Thread

It is also a modification of the square thread. And it has a rounded top and bottom. It can be cast or rolled easily and can not be economically made on a machine. These threads are used for rough

and ready work.

They are usually found on railway carriage couplings, hydrants, necks of glass bottles, and large molded insulators used in the electrical trade.

#16. Trapezoidal Thread

The trapezoidal thread owes its name to the profile of the threads, which have the shape of a symmetrical trapezoid. The trapezoidal thread bears the identification letters Tr and has a flank angle of 30 degrees.

There are three different standards. DIN 103 defines the ISO metric trapezoidal thread. In DIN 380 the flatter trapezoidal thread. And finally in DIN 30295 the rounded trapezoidal thread. Further information can be found in this article: Trapezoidal thread spindle.

Screw Thread Terminology

Knowing the different screw types and sizes is helpful, but to accurately select the right screw for your project, you’ll likely need to know a little about how screw threads work, as well. So, how do screw threads work? Like the screws themselves, screw threads are designed to meet the needs of specific applications.

You can try to find a screw thread chart that outlines all of your different options, but what you really need is a guide to screw thread terminology that answers all your questions and provides a comprehensive rundown of different screw and bolt thread types why they matter.

To help you make the best investments in fasteners for your next project, here’s a thorough guide to screw thread terminology:

- External Threads: External threads (i.e.: male threads) mean the threads are on the bolts or screws. Threads are sometimes on the nuts rather than the bolts or screws.

- Internal Threads: Internal threads (i.e.: female threads) mean the threads are on the nuts rather than the bolts or screws.

- Machine Screw Threads: Machine screw threads are unique in that they are specially designed to mate with threads on nuts or threads present in tapped holes. Not self-tapping threads.

- Spaced Threads: Spaced threads are designed to form their own threads in pre-drilled holes. You’ll most often find spaced threads on self-tapping, wood, and coach screws.

- Lag Screws: Lag screws are just one example of screws that form their own thread in pre-drilled holes. Typically, coach screws are used to fasten metal to wood.

- Self-Tapping Screws: Self-tapping screws are threaded to create their own holes when installed. They form a matching thread in whatever material they are installed into. This makes using self-tapping screws incredibly efficient.

- Thread-Forming Screws: Used with plastic materials, thread-forming screws feature two separate threads: one high and one low. This makes the pullout strength higher while also ensuring plastic does not crack or otherwise break.

- Type U Screws: Type U screws include an unusual spiral thread that is most often driven with a hammer into materials like plastic and metal casings.

- Wood Screws: Wood screws feature a tapered shank with sharp threading.

Why It’s Important to Get the Right Screw Thread

Not all screw threads are going to work with all applications. Each one is tailored to different tasks and different material sizes.

Some will require pre-drilled holes while others have sharp designs meant for drilling directly into softer materials like wood. Other screws vary in thread spacing, which is important for various characteristics of the screw. If using any bolts or nuts, you’ll need to make sure they match the spacing of the screws.

By paying special attention to these characteristics, you can more readily ensure that your choice of screw provides appropriate strength and performance for the application.

FAQ.

What are the three basic types of threads?

There are three standard thread series in the Unified screw thread system that is highly important for fasteners: UNC (coarse), UNF (fine), and 8-UN (8 thread).

What are the most common threads?

Metric, UNC, UNF and More: Thread Types for Fasteners

1. Metric Thread. Metric thread is the most widely used today, and can otherwise be referred to as ‘ISO Metric’ or ‘M’.

2. UNC. UNC stands for ‘Unified Coarse’ and is the most commonly used thread type in the United States of America.

3. UNF. UNF stands for ‘Unified Fine’, which is also a popular thread in the United States.

4. BA. BA are also referred to as ‘British Association’ and are an old-style British thread with numbered diameters.

5. BSF. BSF, or ‘British Standard Fine’ is another old-style British thread and can be used on vintage automobiles and machinery.

What are Class 3 threads?

Class 3 threads are tight tolerance threads that have no allowance and have very tight tolerances. Class 3 threads are often specified for tight tolerance fastener applications in critical use situations where safety and strength are a primary concern, such as the aerospace industry.

How to classify threads?

Thread fit is a measure of looseness or tightness of mating threads. For unified inch threads, there are 3 thread classes for external threads 1A, 2A, and 3A and three for internal threads 1B, 2B, and 3B. All of these are “clearance fits” which indicates that they assemble without interference.

Are R and NPT the same?

NPT is the US standard tapered pipe thread. N stands for National which means American National Standard. P stands for PIPE, and T stands for TAPER with a 60°tooth angle. R is 55 degree sealed pipe thread.

What is the strongest type of thread?

Kevlar(TM) thread is one of the strongest and most fire retardant commercially available threads. It is about 2.5 times stronger than nylon or polyester, has almost no stretch, does not melt, and decomposes at 800F.