Welding is one of the craziest things humans have ever figured out, seriously! It’s crazy how versatile it is, whether it’s on land, in space, or even underwater. Welding allows you to bring dissimilar metals together and glue them together at all sorts of angles.

In the world of welding, we typically work with five main types of welding joints that we use all the time.

What is a Welding Joint?

A welding joint is basically where two or more pieces of metal or plastic join together. They’re formed by welding these pieces according to a specific shape.

A welding joint refers to how the parts to be joined are assembled prior to welding. The metal to be joined is called the base metal. If the part to be welded is not metal, it is called base material.

It is also known as the workpiece or work. The edges of the base metal are often machined, sheared, gouged, flame cut, plasma cut, or bent to prepare them for welding. Welding joint design and metal thickness usually determine how the joint is prepared.

Weld joints must be correctly designed and have adequate root openings to support the ‘loads transferred from one workpiece to another through the welds.

The following are some basic considerations in the selection of any weld joint:

- Whether the load will encounter tension, compression, bending, fatigue, or impact stresses.

- How the load is to be applied to the joint, i.e., whether the load is a static, impact, cyclic, or variable load.

- The displacement of the load in relation to the joint.

- The direction from which the load is to be applied to the joint.

- The cost of preparing the joint.

Weld joint design is based on the strength of the joint, safety requirements, and the service conditions under which the joint must perform. Additionally, how stresses are to be applied during service, and whether tension, bending, or torsion is a factor, must be considered in joint design.

Joint design requirements vary depending on whether the load is static, cyclic, or variable. Joints are also designed for economy or accessibility during construction and inspection.

The American Welding Society (AWS) recognizes five types of welding joints: butt, corner, edge, lap, and tee. Each of these joints can have different configurations where the actual welding happens.

Types of Welding Joints

According to AWS, five basic types of welding joints are commonly used in the industry:

- Butt joint welding

- Tee joint welding

- Corner joint welding

- Lap joint welding

- Edge joint welding

The term weld joint design refers to the way pieces of metal are put together or aligned with each other. There are five basic designs for joints: butt joints, lap joints, tee joints, outside corner joints, and edge joints. Each design shows how the different parts of the joint come together.

Butt Joint

A butt joint, or butt weld, is a joint where two workpieces in the same plane with their edges meeting or with a root opening lying parallel to one another and joined by welding. Common examples of butt joints are the deck plates on a ship and the pipes of an oil pipeline. Both are assembled end-to-end.

In a butt joint, the edges of the metal meet so that the thickness of the joint is approximately equal to the thickness of the metal.

The metal surfaces are usually parallel with each other, although there can be some difference in thickness or misalignment of the plates. A butt joint can be welded from one side or both sides with some form of groove welding.

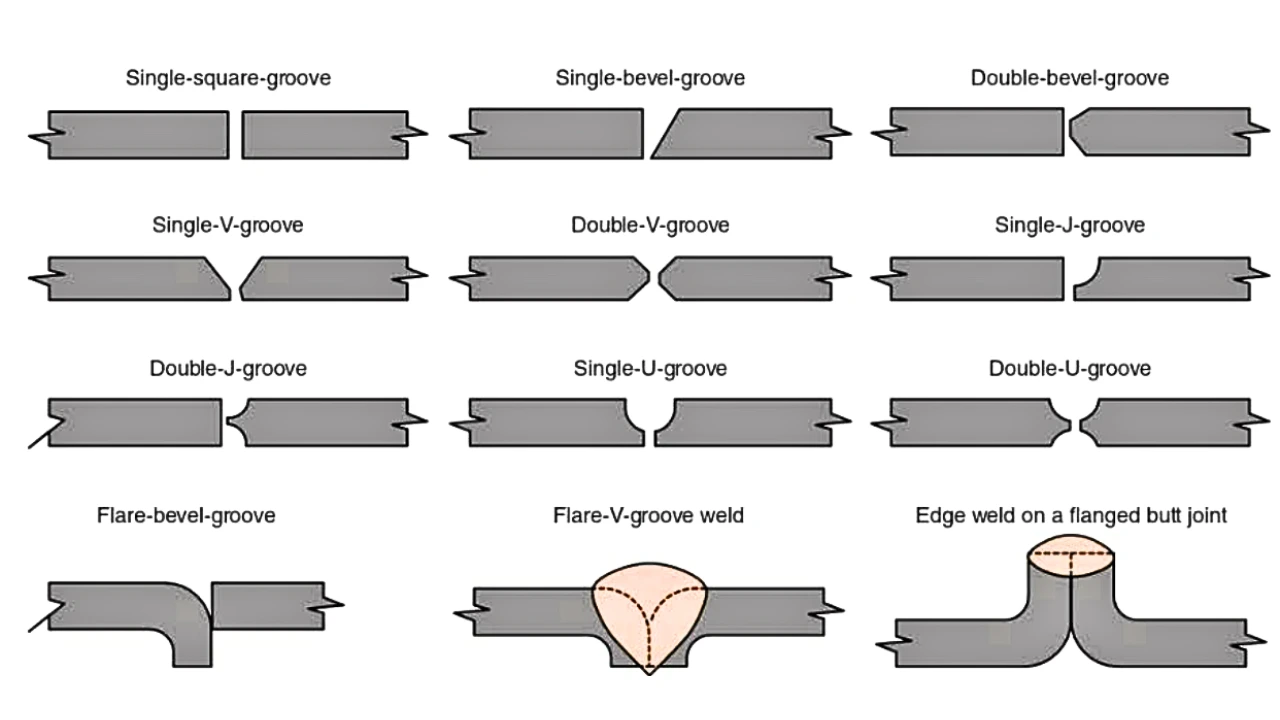

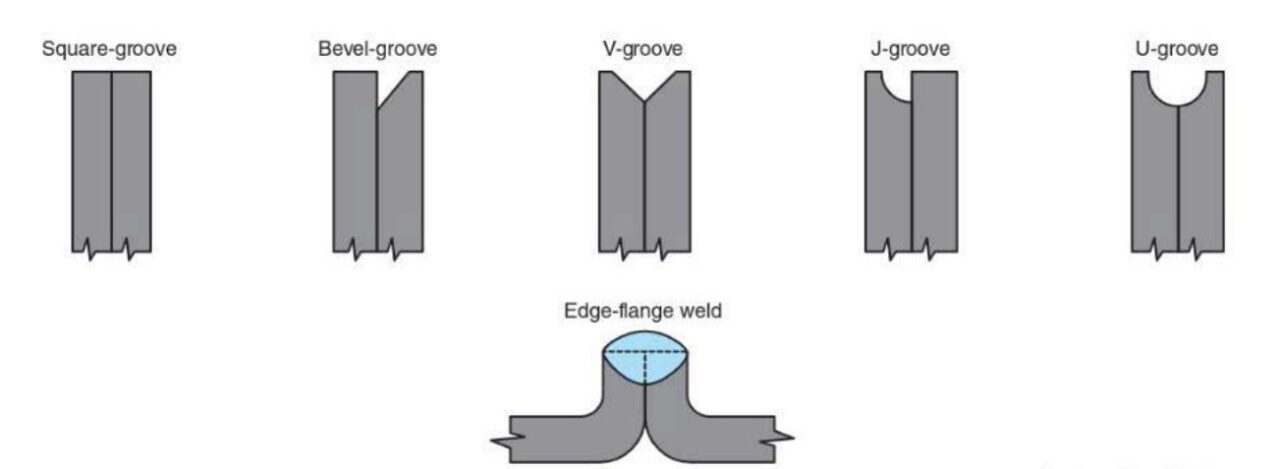

There are a variety of butt joint configurations, depending on how the ends of the pieces being joined are prepared. For quality, welds to be produced on butt joints, the edges of the base metal often require special preparation before welding.

Edge preparation. The area of the metal’s surface that is melted during the welding process is called the faying surface. The faying surface can be shaped before welding to increase the weld’s strength; this is called edge preparation. The edge preparation may be the same on both members of the joint, or each side can be shaped differently.

Reasons for preparing the faying surfaces for welding include the following:

- Codes and standards. Some codes and standards require specific edge preparations.

- Metals. Some metals must be grooved to successfully weld them, such as thick magnesium, which must be U-grooved; or cast-iron cracks, which must be drill-stopped and grooved.

- Deeper weld penetration. With the metal removed by grooving or beveling the metal’s edge, it is easier for the molten weld metal to completely fuse through the joint. In some cases, it is possible to make a through-thickness weld from one side.

- Smooth appearance. The weld’s surface can be ground smooth with the base metal so that the weld “disappears.” This can be done for appearance or so that the weld does not interfere with the sliding or moving of parts along the surface.

- Increased strength. A weld should be as strong as or stronger than the base metal being joined. By having 100% joint fusion and an appropriate amount of weld reinforcement, the weld can meet its strength requirement.

If the base metal is thin, the edges may just be squared without additional machining or cutting. The edges of thin metal may also be bent to form flare grooves or edge-flange joints.

Generally, when base metal over 3/16″ (4.8 mm) thick is used, edges are beveled by machining, arc cutting, or flame cutting. Edge preparation is required to allow the weld to penetrate to the required depth. Thick base metal may be machined, gouged, or flame cut along the upper or lower edges of the joint, or both, to form a double-bevel, V-, J-, or U-groove.

Types of Butt Weld joints

There are different ways to make butt welds, and each has its purpose. Let’s take a look at a few examples of butt weld joints:

1. Square butt Joints.

The square butt joint is intended primarily for materials that are 3/16″ thick or less. Square butt joints require full and complete fusion for optimum strength. For submerged arc welding, materials up to 3/8″ thick with a minimum gap of 1/8″ can be welded.

The square butt joint is reasonably strong in static tension but is not recommended when the joint is to be subjected to fatigue or impact loads, especially at low temperatures. Preparation for a square butt joint requires matching only the edges of the workpieces. Square butt joints are an inexpensive weld joint option.

2. Single Bevel Butt Joints.

A single bevel butt joint is a partial penetrating single bevel groove weld. It is welded from one side and is generally used on metals not more than 1/2″ thick.

3. Single-V Butt Joints.

A single-V butt joint is used on metal from 3/8″ to 3/4″ thick. Preparation for a single-V butt joint is costly because a special beveling operation and more filler material are required than for a square butt joint.

A single-V butt joint is strong in static loading but, like the square butt joint, is not particularly suitable when subject to fatigue or impact loads at the weld root.

4. Double-V Butt Joints.

A double-V butt joint is suitable for all load conditions. The double-V is often specified for stock that is heavier than the metal used for a single-V. Heavy metals that use a double-V joint are typically 3/4″ thick or greater.

For maximum weld strength, penetration must be complete on both sides. The cost of preparing a double-V joint is higher than the single-V. but usually less filler material is required because a narrower groove angle can be used.

To keep the joint symmetrical and warpage of the joint to a minimum, the weld bead must be alternated. The welding should be done first on one side and then the other, with the welder alternating sides until the groove is filled.

5. Single-U Butt Joints.

A single-U butt joint meets all ordinary load conditions and is used for work requiring high-quality welds. The single-U works well on applications joining workpieces 1/2″ to 3/4″ thick.

The single-U joint needs less filler metal than the single-V or double-V joint, and generally, less warpage occurs.

6. Double-U Butt Joints.

A double-U butt joint is intended for heavy metals 3/4″ thick or more on which welding can easily be accomplished on both sides. The double-U joint can meet all regular load conditions. Preparation costs are higher than the single-U butt joint.

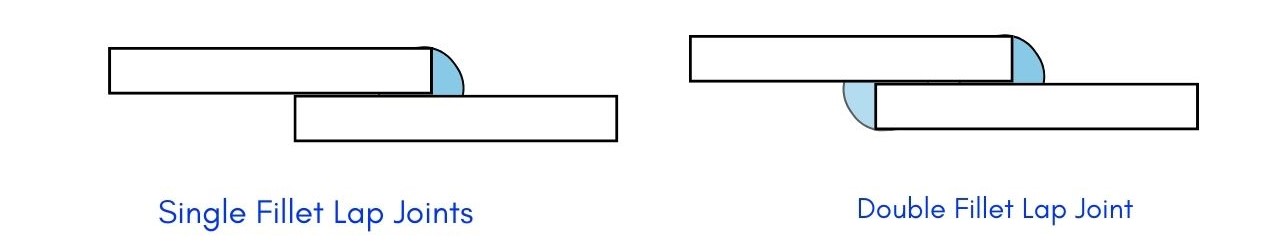

Lap Joint

A lap joint is a weld joint between two overlapping pieces of base metal in parallel planes. A lap joint is one of the strongest joints available, despite the lower unit strength of the filler metal.

In a lap joint the edges of the metal overlap so that the thickness of the joint is approximately equal to the combined thickness of both pieces of metal. The distance the surfaces overlap each other may vary from a fraction of an inch to several inches or even feet.

Lap welds are usually joined by making a fillet weld along the edge of the top surface of one piece with the bottom surface of the other Piece, special edge preparation is not required.

There are several alternate ways of welding lap joints where the weld is made through one or both pieces of metal joining the lap in the center of the overlap.

Lap joints are commonly welded on both sides. An overlap greater than three times the thickness of the thinnest workpiece is recommended. Two basic lap joints are single fillet and double fillet lap joints.

- Single Fillet Lap Joints. A single fillet lap joint is very easy to weld. Filler metal is deposited along the seam on one side of the joint. The strength of the single fillet weld depends on the size of the fillet. Metal up to ½” thick can be welded with a single fillet if the loading is not too severe.

- Double Fillet Lap Joint. A double fillet lap joint can withstand greater loads than a single fillet and is one of the more widely used joints in welding. If the double fillet weld is properly made, its strength is comparable to that of the base metal.

Here are the welding styles for lap joints:

- Bevel-groove weld

- Flare-bevel-groove weld

- J-groove weld

- Slot weld

- Spot weld

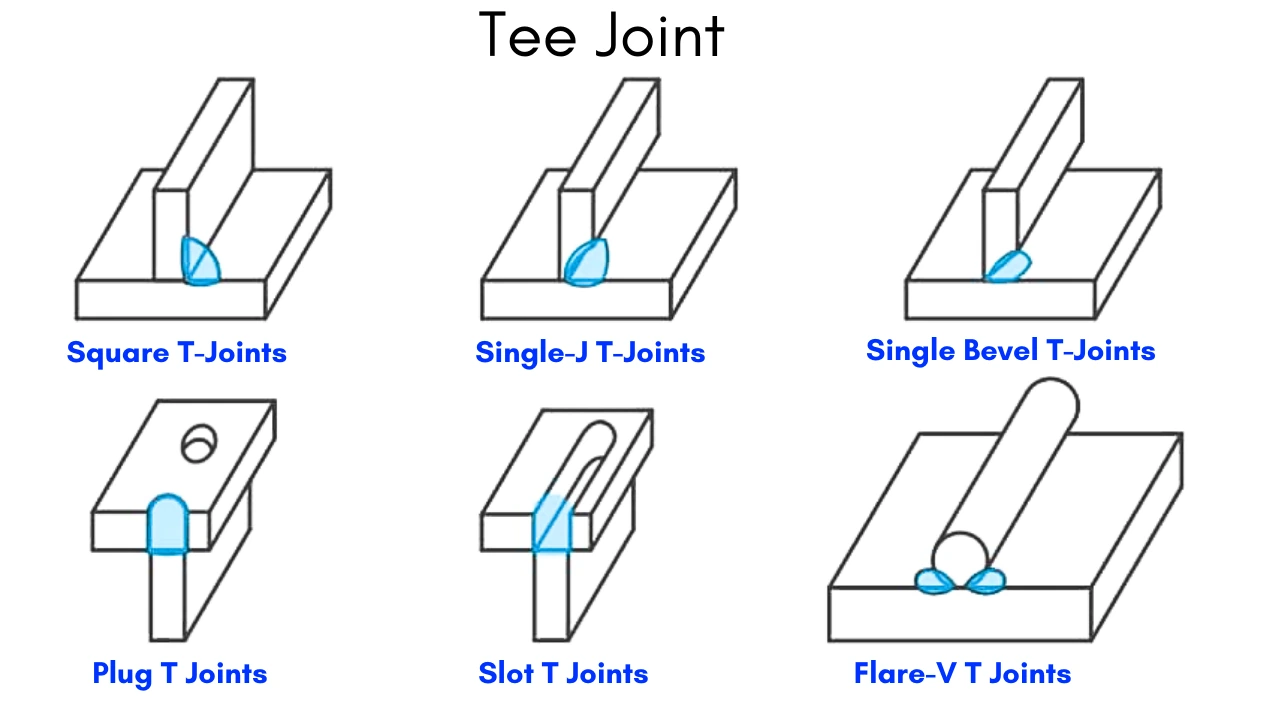

Tee Joint

A T-joint is a weld joint formed when two pieces of base metal are positioned at an angle of approximately 90° to one another in the form of a T.

In a tee joint, the edge of a piece of metal is placed on the surface of another piece of metal. The main difference between a corner joint and a T-joint is that a corner joint is formed along the edges of both pieces, while a T-joint is formed at the edge of one piece and away from the edge of the second piece.

Tee joints can be welded with a fillet weld applied to the surfaces, or a weld can be made in a precut groove on the edge of the joining plate. In a few cases, a fillet weld can be made on the top of a groove weld on a tee joint. Welds can be made on one side or both sides of the joint.

Basic T-joints are square, single bevel, double bevel, single-J, and double-J.

- Square T-Joints. A square T-joint can be welded on one or both sides and requires the use of a fillet weld. Square T-joints can be used for thin or reasonably thick materials where applied loads subject the weld to longitudinal shear. Since the stress distribution of the joint may not be uniform, this factor should be considered where severe impact or heavy transverse loads are encountered. For maximum strength, considerable weld metal is required.

- Single Bevel T-Joints. A single bevel T-joint can withstand a more severe load than the square T-joint since it allows for better distribution of stress. It is generally confined to plates ½” thick or less where welding can only be done from one side.

- Double Bevel T-Joints. A double bevel T-joint is intended for use where heavy loads are applied in both longitudinal and transverse directions, and where welding can be done on both sides.

- Single-J T-Joints. A single-J T-joint is used on plates 1” thick or more where welding is limited to one side. It is especially suitable for welding workpieces that are exposed to severe loads.

- Double-J T-Joints. A double-J T-joint is particularly suitable for heavy plates 1½” thick or more where unusually severe loads are encountered. The joint location should permit welding on both sides.

Here are the welding styles for Tee joints:

- Bevel groove weld

- Fillet weld

- Flare-bevel-groove weld

- J-groove weld

- Melt-through weld

- Plug weld.

- Slot weld

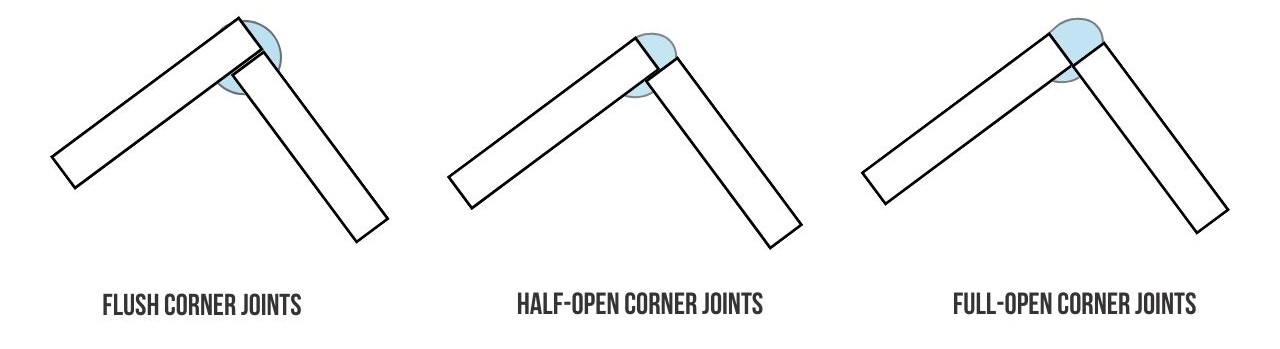

Corner Joint

When you’re dealing with corner joint welding, it means you have two materials coming together to form an L-shape. This type of joint is handy when you’re building stuff with sheet metal like frames, boxes, and other similar things.

A comer joint is a joint formed when two workpieces are positioned at an approximate right angle in the shape of an L. At least one edge of the two pieces is exposed.

The pieces can be joined at any angle, but they are commonly welded at a 90° angle. Corner joints can be welded as inside corners, outside corners, or a combination of both.

Inside corner joints are welded along the inside of the intersection of the two pieces. Outside corner joints are welded along the outside edge of the joint. The edges may be square, beveled, J-grooved, flared, or flanged.

Comer joints are used in many applications to join sheet and plate metal sections exposed to general service loads. Common corner joints are flush, half-open, and full-open.

- Flush Corner Joints. A flush corner joint is designed primarily for welding sheet metal 12 gauge and Lighter. It is restricted to light materials because deep penetration is sometimes difficult to achieve, and the joint is able to support only moderate loads.

- Half-Open Corner Joints. A half-open comer joint is usually more adaptable for materials heavier than 12 gauge. It is suitable for loads where fatigue or impact is not too severe and where the welding can only be done from one side. The two edges of the workpieces are shouldered together so there is less tendency to burn through the plates at the corner.

- Full-Open Corner Joints. A full-open corner joint permits welding on both sides so it produces a strong joint capable of carrying heavy loads. All metal thicknesses can be welded with full-open corner joints. A full-open corner joint provides good stress distribution.

Type of welds used for corner joints:

- Bevel-groove weld

- Corner-flange weld

- Edge weld

- Fillet weld

- Flare-V-groove weld

- J-groove weld

- Spot weld

- Square-groove weld or Butt weld

- U-groove weld

- V-groove weld

Edge Joint

An edge joint is a weld joint formed when the edges of two or more parallel or nearly parallel members are joined. The edge joint is suitable for plates ¼” thick or less and can sustain only light loads.

Edge joints can be combined with butt joints or corner joints and the edges can be squared or beveled. An edge joint is commonly used to join support structures and short lengths of structural steel.

A flanged joint is a joint in which one of the joint members has a flanged edge at the weld joint.

Flange Joint

A flange joint is formed when the edge of one or more pieces of the joint is bent to form a flange. The edges are aligned, and a Weld is placed along the specified edges.

Flare-Groove Joint

Flare-groove joints are formed, then the flanged edges of one or both pieces are placed together to form a single-flare-bevel or double-flare-V-groove.

An edge joint may be constructed using these types of welds:

- Bevel-groove weld

- Corner-flange weld

- Edge-flange weld

- J-groove weld

- Square-groove weld or butt weld

- U-groove weld

- V-groove weld

Advantages of Welding Joints

- The welded joint has high strength, sometimes more than the parent metal.

- Different materials can be welded.

- Welding can be performed at any place, with no need for enough clearance.

- They give a smooth appearance and simplicity in design.

- They can be done in any shape and any direction.

- It can be automated.

- Provide a complete rigid joint.

- The addition and modification of existing structures are easy.

Disadvantages of welding Joints

- Members may become distorted due to uneven heating and cooling during welding.

- They are permanent joints, to dismantle we have to break the weld.

- High initial investment

Application of Welding Joints

Welding is widely used for the fabrication of pressure vessels, bridges, building structures, aircraft and space crafts, railway coaches, and general applications in shipbuilding, automobile, electrical, electronic, and defense industries, laying of pipelines, railway tracks, and nuclear installations.

- Fabrication of sheet metal.

- Automobile and aircraft industries.

- Joining ferrous and non-ferrous metals.

- Joining thin metals

FAQs

What are the 5 basic weld joints?

There are five basic welding joint types commonly used in the industry, according to the AWS:

1. Butt joint welding.

2. Tee joint welding.

3. Corner joint welding.

4. Lap joint welding.

5. Edge joint welding.

Which weld joint is strongest?

TIG welding is often considered the strongest weld since it produces extreme heat, and the slow cooling rate results in high tensile strength and ductility. MIG is also an excellent candidate for the strongest type of weld because it can create a strong joint.

How many basic weld joints are there?

The five basic weld joints include the butt joint, the lap joint, the tee joint, the corner joint, and the edge joint. The butt joint occurs when two members are placed side-by-side or butted together. The weld is made along the seam that adjoins the two adjacent pieces.

What is the weakest weld?

An edge joint is the weakest type of weld join, so isn’t suitable for load-bearing jobs.

What metals Cannot be welded together?

Some examples of material combinations that cannot be fusion welded successfully are aluminum and steel (carbon or stainless steel), aluminum and copper, and titanium and steel. Nothing can be done to alter their metallurgical properties. That leaves changing your process.