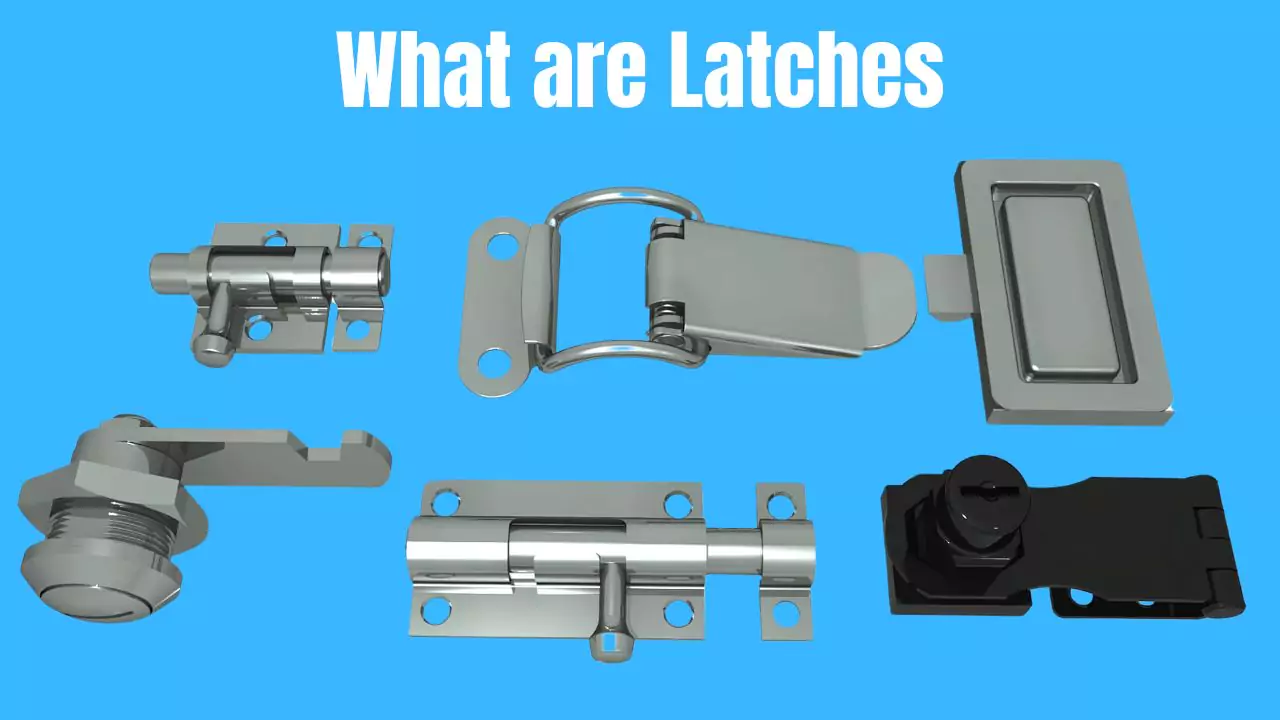

What are Latches?

Mechanical devices like latches are used to keep moving parts temporarily secured together. They work by engaging to secure several components which can be actuated to release and separate the sections.

Latches are usually found on doors and enclosures, but also in seat belts, clamps, straps and retractable systems. Various designs offer different methods of actuation, holding style, and mounting options.

What are door latches?

An example of an encapsulated latch are door latches. They are used for keeping doors and gates closed, hence the name. Doors and gates can be held in place by sliding bolts or hooks that maintain a closed position regardless of whether the door swings or slides open.

Various examples of door latches are doorknobs. They are primarily architectural and include a latching mechanism, a locking mechanism and two knobs on either side of a door.

The latch inside the doorknob functions as a spring and bolt mechanism and can be activated by turning the knob on either side. A quarter turn unlocks the latch which is fully engaged with a 90° soft-stop rotation.

For Some designs use levers instead of knobs for both aesthetics and ease of use. Elegance and differing forms of architecture appreciate doors having handles that serve as levers. They have better grip than knobs.

For emergency exits, latches referred to as panic bars are used. Panic bars (also known as crash or push bars) are set in motion by pushing a large bar fixed onto the door handle.

These latches are built to open quickly and with little resistance to help people escaping from being trapped in panic situations during emergencies.

Most modern doorknobs come with a locking construction preventing one side from unlocking the latch. A number of modern doorknobs come with more sophisticated electric and electronic features providing complex locking systems where the latch is released with power and control.

Door latches can be divided into three types: deadbolt, deadlatch, and deadlock. These types differ in the way the latch is locked and unlocked. Below, the mechanisms, construction, and characteristic of these types are described.

Types Of Latches

A basic latch includes a base, bolt, and box or hole. The bolt of the base is mounted on the door, while the box is placed on the door frame, and when the bolt is moved, or rather, slided into the box, it activates the latch and secures one end of the bolt to the door and the other end to the frame securing the frame into place.

This simple structure has been applied in the creation of various forms and types of latches which some are further described in the next sections.

#1. Bolt Latches

Bolt latches or latch bolts are known simply as latching devices that have a bolt, a handle, a back plate, a set of barrels, and a box sometimes referred to as a striker. The bolt of the latch is secured by the barrels preventing the bolt from moving.

The two form a gap or an opening which allows a handle to be fitted into. A bolt latch is capable of being locked or unlocked by moving the bolt to the socket and then sliding it. The most recognized type of lid bolt latch, or barrel bolt is used on doors, windows, and gates.

#2. Spring Latches

A spring latch has all the characteristics of a bolt latch with the addition of a spring for automatic bolt extension. In some cases the spring is designed to hold the bolt in its retracted position.

Spring latches can’re created in a multitude of ways. A standard spring latch is comprised of an L-shaped bolt or plunger that is equipped with a clip or pin hole and a back plate with two lips with holes to attach the clips.

A spring is placed under the lip and over the pin to allow the plunger to be in rest position. The construction of a spring latch is found also in deadlatches and slam latches. Deadlatches and slam latches have distinctive factors that differentiate them from ordinary spring latches.

#3. Slam Latches

Slam latches, or push-to-close latches, are made for doors that must automatically latch when shut. Instead of bolts, slam latches used cams to engage the striker or doorframe.

Slam latches are usually rounded or chamfered at the edges so they can easily retract when they strike against the striker. A spring loaded can keeps the cam in the raised position. The cam either turns or slides into place when triggered.

Slam latches are built to tolerate an excessive number of openings and closings without putting significant strain upon them, in comparison to spring latches.

Therefore, they can be found on doors that experience massive flow of traffic in commercial and industrial settings. Moreover, slam latches are common in emergency exits in which the handle can be pushed for rapid and easy unlatching.

Other forms of push-to-close or slam latches are:

- Spring bolt latches

- Pin latches

- Explosion venting latches

- Tipper latches

- Toggle latches

- Push-button latches

- Slam action strike latches

- Cab latches

- Paddle handles

- Compartment latches

- Cane bolt latches

#4. Swinging Latches

Swinging latches, or also termed as swinging door latches, function the same as slam latches do. These push-to-close latches are self locking when the door is shut.

It has a spring actuator that holds the bolt in the extended position, which has a rounded edge so that the impact onto the striker allows the bolt to easily retreat.

#5. Cam Latches

You may come across cam latches in the construction of drawers and cabinets, among other types of furniture. Cam latches work by turning a knob or a key, which moves an arm on the other side of the door.

Like many other quarter-turn devices, cam latches work on an uncomplicated principle and do not use a strike plate, box, or hole within the frame.

Rather, they seal the door or enclosure by obstructing only one side which makes them unsuitable for doors that swing or protrude beyond the frame.

Examples of cam latches include:

- Cam locks

- Folding T Handles

- Actuator handles

- Swing handles

- Defeater handles

- Quarter turn latches

#6. Cabinet Latches

Furniture set in place with a hinge, handles, and guide rails, such as drawers and cabinets, will always have a latch installed. Cabinet latches can be of various forms. The most popular are bolt, spring, cam, and slam latches.

In most cases cabinet latches are made from stainless steel, brass, copper, and anodized aluminum. These strengthen the look and the construction of the latches since they do not corrode, ensuring the cabinet latches remain functional over time.

All cabinet latches are made using a variety of metalworking techniques such as casting, cutting, or forging.

For ornamental purposes, the dies and molds used to craft latches are often more advanced than the basic patterns for latches they are more advanced than standard latch patterns used for most latches.

#7. Gate Latches

Gate latches are made stronger and thicker than cabinet latches serving the same purposes as cabinet latches for large doors and gates. Like cabinets, gates are designed with architectural features which makes them truly one of a kind.

The most common types of gate latches include barrel bolts, bars latches, and heavy-duty industrial latches. Slam latches and spring latches, commonly referred to as swivel locks, also serve their place in gate latches.

Made from heavier gauge sheets or plate metal, the latches are cut into shape by applying larger compression forces.

Gate latches are commonly made from galvanized steel or stainless steel, especially grade 304 steel since they are highly corrosion-resistant. These materials are perfect for most industrial and commercial purposes as well as residential use.

#8. Turn Latches

This type of latch looks quite a lot like a cam latch, seeing how it’s shaped. To actuate the latch all that is needed is a 90 degree turn of the knob, which makes this latch incredibly simple. the mechanism contains an arm or cam which moves into rotation when the knob is turned.

Some turn latches are equipped with a keyed knob for better security. Moreover, some models require additional steps such as pushing or pulling before turning the knob to unlock the latch. These double-action features enhance security in preventing unintentional release of the latch.

#9. Compression Latches

A compression latch is a type of cam latch with advanced features. It incorporates a mechanism that provides a compressive force between the door and the frame while closed.

This can occur by pushing the door and engaging the latch or turning the screw action latch. Unlike ordinary cam latches, these have flexing arms that are slightly pressed against the enclosure frame. The arms of compression latches are stiffer than those of ordinary cam latches.

Incorporated gaskets or rubber trim round the edges of the doors of stoppers serve more than one purpose. These are standard in enclosures containing electronic and control equipment.

Latches tightened by these components create a seal that protects the internal components from dust and moisture. The gaskets also prevent unauthorized access to the device while dampening vibrations that could cause noise and wear on the hinges of the doors.

Types of Compression Latches

- Lift and Turn Handles: In lift and turn compression latches, maximum compression is achieved when the handle is lifted, turned 90 degrees, then pressed down. The rotation direction is selected at the time of installation.

- A With Large T: Large T compression latches feature a T handle which is beneficial in areas with severe vibrations. The compression latch is opened by turning it counterclockwise while turning it clockwise locks it.

- Panel: With panel compression latches, the latch mounts behind the panel and can interface with computers, HVAC tools, and machinery.

- Round: Rounded compression latches are intended for a circular slot, either pre-cut or milled on an enclosure’s surface. They are inserted flush and utilize low-profile fasteners. The handle of round compression latches is incorporated into the latch. The handle position is a possible indication that the latch is disengaged.

- Tool Activated: Tool Activated compression latches resemble standard turn latches, but with a cam that pulls inward towards the latch as the door is being closed to enhance the seal.

- Trigger: Trigger compression latches work like standard trigger latches with the exception that in this case, a tighter seal is created when the cam rotates and draws the slide and bracket together. The different types of trigger compression latches can be either flush or pop up from the door.

#10. Magnetic Door Catches

A magnetic door catch is made up of a catch body that has a permanent magnet and a magnetic strike plate attached to ferromagnetic material.

Used for automatic and easier latching of cabinet doors, other designs use two magnets, one on each side of the door and frame. These are suitable for lightweight and low-traffic doors.

The magnetic catch has a hollow chassis often constructed from non-ferromagnetic metal or plastic. A bar magnet, which is positioned between steel plates on the top and bottom sides, can be found inside the hollow casing.

These steel plates serve to enhance the concentration of the magnetic field as well as ensure contact with the striker plate.

The magnetic catch is already installed on the door jamb or frame and works with a strike plate that is mounted on the edge of the door. The catch is surface-mounted or concealed.

The proper operation of the system is achieved only if the door is closed so that the magnet physically contacts the metal strike plate requiring a strong magnetic pull.

#11. Draw Latches

A draw latch, also called toggle latch, incorporates a part that is constantly in tension. Such a configuration is advantageous in situations where a strong closing force is necessary, so that secure seals are created and leakage or ingress of dust and water is avoided.

Draw latches can also be designed to withstand unintended opening. They are often found in electronic enclosures and control panels for the equipment.

As far as draw bolts go, the most basic features draw latch design include the two hooks with the following fishing terms: a semicircular hook blade of claw made from flat rod stock and a rectangle plate with a cut-out claw shaped as a hook known as the receiver, striker or catch that is formed from a sheet of metal. Some designs have rod or wire shaped into a loop that serves as the second hook.

The blade and hook, or two hooks come together under stress, engage each other to perform latching. One of the hooks is attached to the lever with a pin and the tension is either hand pulled or pushed towards the lever.

Subtypes of draw latches are:

- Rubber T-handle latches

- Hood latches

- Living hinge latch

- Over center latches

- Under center latches

- Twist latches (link lock, butterfly latch, wing latch)

#12. Over Center Latches

Known to apply great closing force while needing an effortless actuator force in shift to a draw latch, over center latches are example of the foregoing type.

The dislocated position of the lever guarantees the delivery of mechanical advantage hence the great tension but with lack of effort in releasing the latch.

The term ‘over center latch’ is defined by its unique over center lock point. After the lever has been pushed past this point, the latch is captured and the force of closing is supported by the hooks.

#13. Cane Bolt Latches

Cane Bolt Latches are The bolt with an L-shaped configuration forms a barrel secured to a frame by way of dual knees. Cane bolt latches possess a simplistic design. Bolt engagement is accomplished by rotation and forward movement into the keeper.

Reverse movement disengages the bolt, thereby unlocking the latch. Cane bolt latches, are offered in right and left configurations and are made of steel with corrosion resistant coatings.

They feature two holes for screws for mounting onto wood or other materials, while some models are offered without holes for direct welding to a door.

#14. Pawl Latches

The proper definition of pawl latch is a latch with a cam that rotates for locking or unlocking purposes. The pawl turns a predetermined angle to lock the latch to the keeper or door frame.

The same amount of rotation in the opposite direction releases the latch. The set position for both the closed and open configurations of the latch are kept in by the pawl.

A wide variety of pawl latches can be found installed on metallic surfaces, such as those housing electronic components, as well as in HVAC systems, buses, trailers, RVs, and boats.

#15. Multi-Point Latches

Multi-point latches consist of a handle which is connected to two long bars that are released once the handle is turned. This shifts the position of the bars so that they can be engaged with the keepers, and for reversing the handle, there is no engagement.

They are also referred to as three-point latches, and are found commonly in doors and metal cabinets, particularly for tall cabinets that have long doors.

The handle of multi-point latches is equipped with a rotating mechanism that changes position to rotate the tips of the bars into the upper and lower keepers.

This results in the tools being extended just enough to allow them to properly engage with the frame or the edge of a cabinet.

The movement of the handle is capable of locking all points of the door in one swift movement.

#16. Quarter Turn Latches

The phrase “quarter turn latch” encompasses many different types of latches, all of which operate by means of a quarter turn of a cam. Because of this diversity in their design, these latches incorporate a wide array of tools, keys, and other closures for opening and closing them.

Quarter-turn latches integrate the utmost level of security resistance against tampering or unauthorized access to enclosures. They can be constructed from zinc, plastic, steel, and stainless steel, and are often plated in chrome or black powder coated.

In addition to offering a variety of sizes and cam styles, quarter-turn latches also provide optional key, lock, and dust cover accessories, as well as finger pulls and padlock cups.

#17. Trigger Latches

Trigger latches are unique because they are flush mounted and placed directly onto doors and enclosures.

These compression type latches features a lock which is located below the trigger. The trigger itself can be easily pushed and when done so, the trigger will allow the pawl to drop and unlock the door.

The lever of the trigger once pushed will be lifted and serve as a door handle. Trigger latches can be constructed with or without locks and can have raised buttons on the trigger for easy operation.

#18. Twist Latches

Twist Latches are also referred to as butterfly latches, which contain a rotating cam that is connected to a straight piece of a slide that has a curved end, which is rotated by the cam.

The latch’s keeper is a flat metal piece similar to slide, which has curved side aiding in the connection between slide and bracket.

The slide in question moves and rotates over the bracket mounted on the cabinet, cupboard, case, door and the slide is tightly held in place by the cam’s rotation.

Twist latches are available in a variety of designs and methods of mounting. They are often found on closures, cases, containers, shipping containers as well as instrument cases. They are often custom fitted with slides of various lengths and may include springs.

#19. Rotary Latches

A rotary latch is made of a latching mechanism, an actuator, and a cable. In most cases, a bolt on the other side meets with latching mechanism.

When actuated, the cams or rotors of the rotary latch turn or rotate. It has a spring loaded arrangement that offers a push-to-close purpose which is the same as a slam latch

The remote actuation capability is what makes the rotary latch different from other types. The actuator is remote to the latch because it is connected to the latching mechanism through cable.

In pulling the actuator, the rotors are pulled to rotate and release the latch. Since the actuator only pulls in one direction, a spring loaded mechanism is required to return the rotor to the original position.

Single and double rotors can be integrated within a rotary latch. A single rotor rotary latch has the basic function of retaining a door or panel so that it does not open.

While double rotor rotary latches have two single rotors that are mirror images of each other and placed side-by-side.

Greater rigidity brought by the two rotors that support the bolt is one of the primary merits of a double rotor latch, along with greater tolerance to misalignment. In addition, double rotor latches also have wider catch openings than single rotor latches.

Another grouping of latches includes distinctions based upon a unit’s operational stages in a sequential manner, defining them as either single-stage or two-stage latches. Sequentially, a single-stage rotary latch performs the basic latching operation only.

In comparison, a two-stage rotary latch has two latching positions: one is a secondary partially closed (false close) position and the other is a primary fully closed latch.

Two-stage latches are required to remain fully closed at all times, but, should the primary stage fail, the secondary stage prevents the door from swinging open uncontrollably. This type of rotary latch is widely applied in the automotive industry.

#20. Hasps

The hasp lock is an uncomplicated form of fastening that is characterized by a pin or bolt in a plate hasp. The bolt pin forms a perfect needled ring and then it is attached to ‘stripl brace’, which hangs on the door frame or the metallic hinged on the walls.

From the upper side, the hinge is narrow shaped allowing rotational movements and attached to the strap of the metallic block.

Instead of the bolt pin, the padlocks can be used with less access on the pin for the best protection.

The hasp locks is a known type of padlock that has the pin encased within the hinge of the strap allowing zero access not the space below. Rotating the strap will freely lift the bolt pin meaning a numbered lock is applied to maintain the region.

#21. Hook and Eye Latches

Perhaps one of the simplest types of latches is the hook and eye latch. They are usually made out of metal castings and, bent wires and rods.

Casting provides the added advantage of intricate designs along with decorative purposes hence why the hook eye latch is the most commonly used latch in households.

The hook is the arm of the latch which is attached to the door while the eye is the catch into which the hook slips when the latch is closed.

#22. Bars

Yet another example of primitive form of latches is bar latches which are wooden or metallic beams wielded into bolts. Designed to withstand great force, these robust latches are used for securing gates and large doors to prevent them from being forced open.

The bolt sits in a sliding bracket that allows vertical motion while residing in sockets fixed to the wall. The bar is secured with strong cleats or hooks. The bar is secured by sliding it into a hole, or manually positioning it onto the cleats.