A piezometer is a geotechnical sensor used to measure pore water pressure (piezometric level) in the ground. Designed to measure pore water pressure in soil, earth/rock, foundations and concrete structures.

Piezoelectric or pore pressure gauges provide important quantitative data on the magnitude and distribution of pore pressure and its evolution over time.

It also helps to assess seepage patterns, potential areas of piping and the effectiveness of seepage control measures that have been implemented.

It is considered one of the most important geotechnical monitoring tools, it is also interesting to study. Let’s take a closer look at piezometers, their types, working principles, applications and functions.

What is a Piezometer?

A piezometer is a device used to measure fluid pressure in a system by measuring the height to which a column of fluid rises against gravity, or groundwater pressure (more precisely, a piezometric head) at a specific point.

A piezometer is designed to measure static pressure, so unlike a pitot tube, it is not directed toward the fluid flow.

Observation wells provide information about the water level in the formation, but must be read manually. It can automatically read multiple types of electrical pressure transducers, making data collection more convenient.

The first piezometer in geotechnical engineering was an open well or standpipe (sometimes called a Casagrande piezometer) placed in an aquifer.

Casagrande piezometers usually have a solid chamber to the desired depth and a slotted or screened chamber in the area where the water pressure is measured.

Casings are sealed over drilled holes with clay, bentonite, or concrete to prevent surface water from contaminating groundwater sources.

In confined aquifers, the piezometer water level does not exactly correspond to the water surface, especially if the vertical component of the flow velocity is large.

In an artesian aquifer, the piezoelectric water level represents the aquifer pressure, but not necessarily the water level.

Piezometer wells can be much smaller in diameter than production wells, and 5 cm diameter standpipes are common.

Piezometers in durable housings can be buried or pushed into the ground to measure groundwater pressure at the installation site.

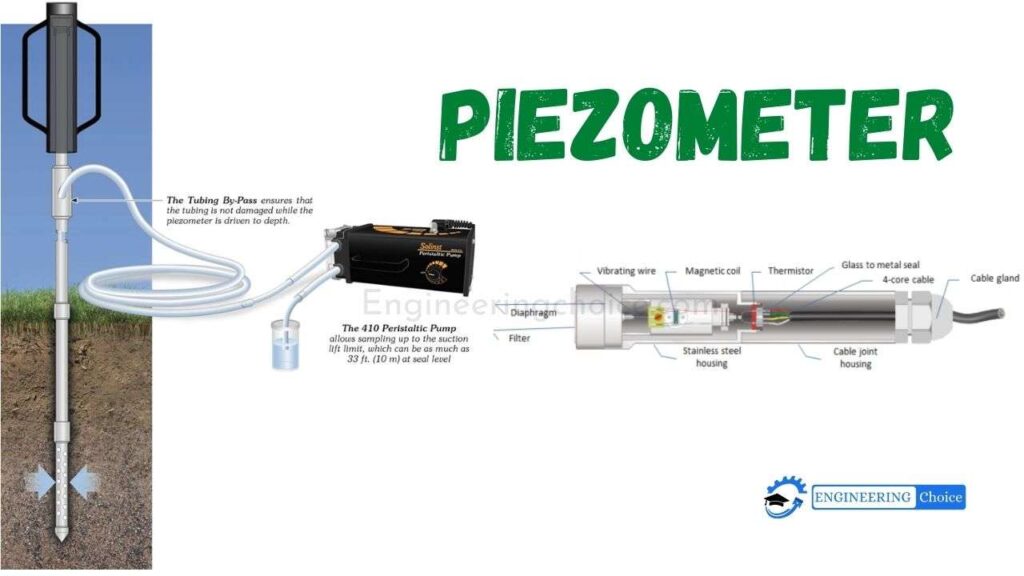

A pressure gauge (transducer) is a vibrating wire, air pressure, or manometer that converts pressure into an electrical signal.

These piezometers can be read faster or longer than basic readout piezometers because they are attached to a surface that can be read by a data logger or portable reading unit.

Principal of Piezometer

Understanding pore water pressures is pivotal because they constitute a fundamental element of effective stress, an important concept in soil mechanics.

The principle of effective stress indicates that any measurable impacts resulting from a stress change, such as compression distortion and alterations in shearing resistance, are exclusively attributed to changes in effective stress, factoring in time effects.

While reasonable estimates can be derived for total stresses (despite the existence of sensors for measuring them), the measurement of pore water pressures is indispensable.

This is where the significance of piezometers truly shines—they play a crucial role in accurately gauging pore water pressures, making them indispensable in geotechnical applications.

A thorough examination of pore pressure is crucial for monitoring post-construction behavior and identifying potential hazards that could jeopardize the stability of structures, foundations, and associated elements.

Additionally, it furnishes essential data for enhancing design, contributing to safer and more cost-effective construction practices.

Why is a piezometer used?

A piezometer is an instrument used to measure the pressure of groundwater, in dams, pipes, and other conduits, allowing its properties to be monitored and controlled when faced with an excavation, borehole, or drainage.

It is an essential tool to carry out this type of work with safety and precision. The use of piezometers has the following purposes:

- Studying the effect of water in soil or rock is to reduce the bearing capacity of soil or rock. This effect becomes more obvious at higher pore water pressures and eventually leads to the complete loss of soil bearing capacity in some cases.

- Determination of groundwater level and flow patterns

- Determines water flow patterns in soil/rock embankments, concrete dams and their foundations.

- To delineate the phreatic line.

How does a piezometer work?

Piezometer is used to measure underground water pressure. It converts the water pressure into a frequency signal through a diaphragm and a tensioned steel wire. As the diaphragm pressure changes, the wire tension changes.

A vibrating wire piezometer basically consists of a high-strength magnetic tension wire, one end of which is fixed and the other end of which is attached to a fixed diaphragm that deflects in proportion to the increase in applied pressure.

As the pressure changes, the diaphragm deflects proportionally, which affects the tension of the stretched wire. Therefore, changes in pore pressure directly affect wire tension.

The wire is pulled by a coil magnet. Proportional to the tension of the wire, it resonates at the frequency “f”, which can be determined as follows:

f = {[σg/ρ] ^1/2}/ 2l Hz

Where:

- σ = tension of the wire

- g = gravitational constant

- ρ = density of wire

- l = length of wire

The resonant frequency at which the wire vibrates induces an alternating current in the magnet of the coil.

Pore pressure is proportional to the square of frequency and the Encardio-rite Model EDI-51V Readout Logger (Data Logger) can display this directly in engineering units.

Types of Piezometers

#1. Standpipe Piezometers.

The Standpipe Piezometer (also known as a Casagrande Piezometer) is used to monitor piezometric water levels in vertical boreholes and offers a simple and economical method for measuring water pressures in soil and rock.

The Standpipe Piezometer typically comprises two parts: at its lowest point is a porous piezometer tip; connected to the tip is a riser pipe which continues upwards out of the top of the borehole.

To measure the borehole water level, the filter tip zone is packed with sand and then backfilled above.

To isolate pore water pressure at the filter tip, a bentonite seal is required between the sand filter zone and the backfill.

Alternative filter tip types may be driven or pushed into soft soil, and different tip designs are available to suit various types of ground.

#2. Vibrating wire piezometer.

A vibrating wire piezometer, or VWP, is a type of piezometer that measures the pore water pressure at a certain elevation by converting the pore water pressure at it’s installation elevation to a frequency which is then recorded and can be converted back into applicable engineering units.

They are very useful for measuring pore water pressures over time, as they can be easily fitted with a data logger.

Using a VWP with a data loggers allows groundwater readings to be taken constantly, without the need for someone to be present on site to take the readings.

#3. Pneumatic Piezometers.

A pneumatic piezometer is activated by gas pressure. It can be installed in a borehole, embedded with a filler or hung on a large diameter standpipe. Readings are taken with an pneumatic indicator.

Pneumatic piezometers are usually used to measure pore water pressure in fills or boreholes. It comprises of a pneumatic piezometer, twin tubing with connector fittings and a pneumatic readout.

The pneumatic piezometer is typically sealed in the borehole. The twin-tubing transports the gas to and from the piezometer.

The portable pneumatic readout comes with an internal supply tank which holds the compressed nitrogen gas which activates the piezometer for reading.

#4. Titanium piezometer.

The titanium piezoelectric meter is a 4-20 mA device compatible with industrial data loggers. Typically used for drop down testing.

The titanium piezometer is used to monitor water levels and pressure, pore-water pressures in corrosive environments such as salt water, rapid changes in pore-water pressure such as those produced by earthquakes, and water levels in pumping tests.

#5. Electric Piezometers.

The next types of piezometers include electric piezometers that consist of a deflecting diaphragm and a porous filter divided by a small reservoir of water.

A vibrating wire or a strain gauge is used to calculate the deflections of the diaphragm. The piezometer-measured results are then converted to an equivalent pressure using proper calibration.

The next procedure is exactly similar to the open standpipe piezometers. The electric piezometer is inserted into a borehole while the annulus between the porous filter and the borehole is filled with cement/bentonite grout.

Water from the ground pushes itself due to buoyant force into the reservoir and causes deflections in the diaphragm until the pressure inside the reservoir is the same as the pore water pressure (piezometric level) in the ground at the elevation of the porous filter.

If an electric piezometer is installed above the current groundwater table, the pore pressure in the soil is negative and the water in the piezometer will be drawn out of the reservoir.

If this happens, the piezometer will be filled with air, leading to its dysfunction.

#6. Hydraulic Piezometers.

The third type of piezometer is the hydraulic piezometer which consists of a porous filter containing a reservoir of water, separated from a pressure gauge via resilient and water-filled tubes.

These tubes circulate water through the system to remove air and ensure that the reservoir remains filled with water.

The piezometer measures overall hydraulic pressure from which pore pressure can be calculated.

Difference Between Monitoring Wells and Piezometers

There are some differences between shallow monitoring and piezometers. They are both pipes that allow water to rise and fall as a way of measuring the level of groundwater.

Shallow monitoring wells have breaks in the length of their pipes, which are below the ground. This allows them to access the groundwater.

The shallow monitoring well measures the water pressure along the length of the entire pipe. Some people like the monitoring well for this reason.

Other names for monitoring wells are observation wells, perforated pipes or open-sided wells.Another way to measure groundwater is with a piezometer.

Instead of measuring the level of groundwater throughout the entire pipe, piezometers measure groundwater at the bottom of the pipe.

Another name for a piezometer is a cased well. It is important to understand the differences between monitoring wells and piezometers.

Because, depending on what you want to measure, you will need a specific meter.

Piezometer Applications

Piezometers measure pore water pressure and groundwater level and provide essential information for:

- Understand basic site conditions.

- Determining the safety factor for filling

- Prediction of slope stability.

- Designed for lateral earth pressure.

- Evaluating the effectiveness of the drainage plan.

- Check the operation of the containment systems.

Advantages of Piezometer

- Simple and reliable

- It is used to measure the static pressure of fluids in vessels.

- One of the main applications of piezoelectric transducers is the measurement of pore water pressure/groundwater level.

- It helps to calculate soil and rock performance.

Disadvantages of Piezometer

- A piezometer cannot be used to measure the static pressure of a gas because gas does not form a free surface.

- Piezometers are not suitable for measuring vacuum pressure (although they can be used). Because vacuum pressure pulls air into the container/vessel. It is only useful when the static pressure of the liquid is greater than atmospheric pressure (gauge pressure).

- Piezometers are not suitable for measuring high pressure in light liquids. Because in this case the piezometric head is very high. It requires a long glass tube and is difficult to handle.

FAQs

What is a piezometer used for?

Piezometers are the geotechnical sensors that are used to measure pore water pressure (piezometric level) in the ground. It is designed to measure pore water pressure in the soil, earth/rock fills, foundations, and concrete structures.

What is the difference between a manometer and a piezometer?

While a manometer is utilized to measure gas pressure, a piezometer is employed to do the same for liquids. Manometers, which contain mercury and oil, are used to gauge gas pressure, whereas peizometers, which contain mercury and water, are used to gauge liquid height.

What is the difference between a piezometer and a pressure gauge?

A piezometer is an ordinary tube that is vertically connected to a liquid system for which the pressure must be measured. A pressure gauge is used to measure fluid intensity, as well as to set up and tune fluid power machines.

How does a piezometer measure water level?

Piezometer is used to measure underground water pressure. It converts water pressure to a frequency signal via a diaphragm and a tensioned steel wire. A change in pressure on the diaphragm causes a change in tension of the wire.

When can piezometer not be used?

It cannot be used to measure the gauge pressure of a gas i.e. leakage of gas through a piezometer. It cannot measure the vacuum pressure. Instead of a column of liquid going up in the tube, the atmospheric air will enter into the pipe through the glass tube.

How accurate is a piezometer?

High Resolution: VW piezometers provide a resolution of 0.025% FS. High Accuracy: Most ranges provide an accuracy of ±0.1% F.S.