What is Plug Weld?

A plug weld, also known as a rosette weld, is a process that fuses two metals together by making a weld inside small circular holes.

This typically involves two overlapping sheets or pieces of metal with the holes in the top one. The weld fills the hole in the uppermost material, joining the two workpieces together.

Creating a circular weld similar to spot welding, the difference is that plug welds can be performed where difficult angles or a lack of space make it difficult to use a spot-welding machine.

Plug welds are also a good alternative for when a spot welder is not available and, if completed properly, these joins can be stronger than a spot weld.

Plug Welding Process

The plug welding process can be broken down into five steps, as follows:

1. Workpiece Preparation:

To avoid any welding defects, it is important to first clean the workpieces.

2. Marking Out:

Next, mark out the position of your plug welds on the uppermost workpiece (which is generally the thicker of the two), making sure to evenly space the welds if you are using more than one.

3. Preparing the Hole

Once you have marked the position of the welds, it is time to make the holes for the plug welds to fill. This is commonly done by drilling through the top workpiece.

The size of the holes differs depending on the size of the workpieces being joined, with thicker sheets requiring larger holes but, as an example 7.5mm should be large enough for 0.8 or 1mm sheets.

4. Clamping:

It is important to use a plug weld clamp to hold the metals together and stop them moving during the welding process

5. Make the Weld:

The final stage is to make the plug weld itself; this requires experience and practice to master. Most welders recommend starting by welding around the edge of the hole with the welding gun at an angle to ensure fusion, as with a successful fillet weld.

Once the outer edge is secured, you can work in circles towards the centre to complete the weld. This technique allows the bottom metal to come up to temperature with the top metal, improving the weld strength and reducing the chance of a defect occurring.

However, more experienced welders are able to begin in the middle of the circle, using their experience to see how the weld pool flows while ensuring there is good penetration on the back plate.

Common Plug Welding Mistakes

Here are the common welding mistakes mentioned that you must avoid:

- Making the holes larger than optimum.

- Not cleaning or over-cleaning the metal plates.

- Over burning the metal sheets.

- Making the hole too thinner which results in burning.

- Inexperienced welder trying to plug weld for the first time.

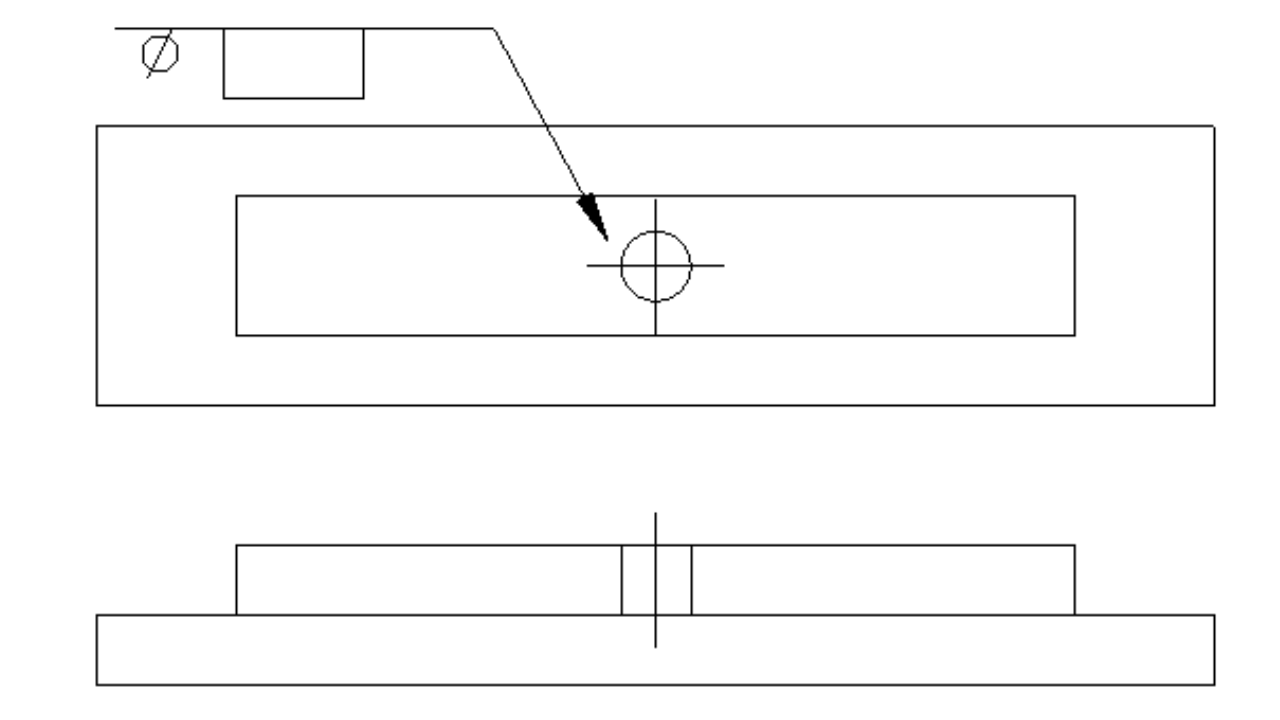

Plug Weld Symbols

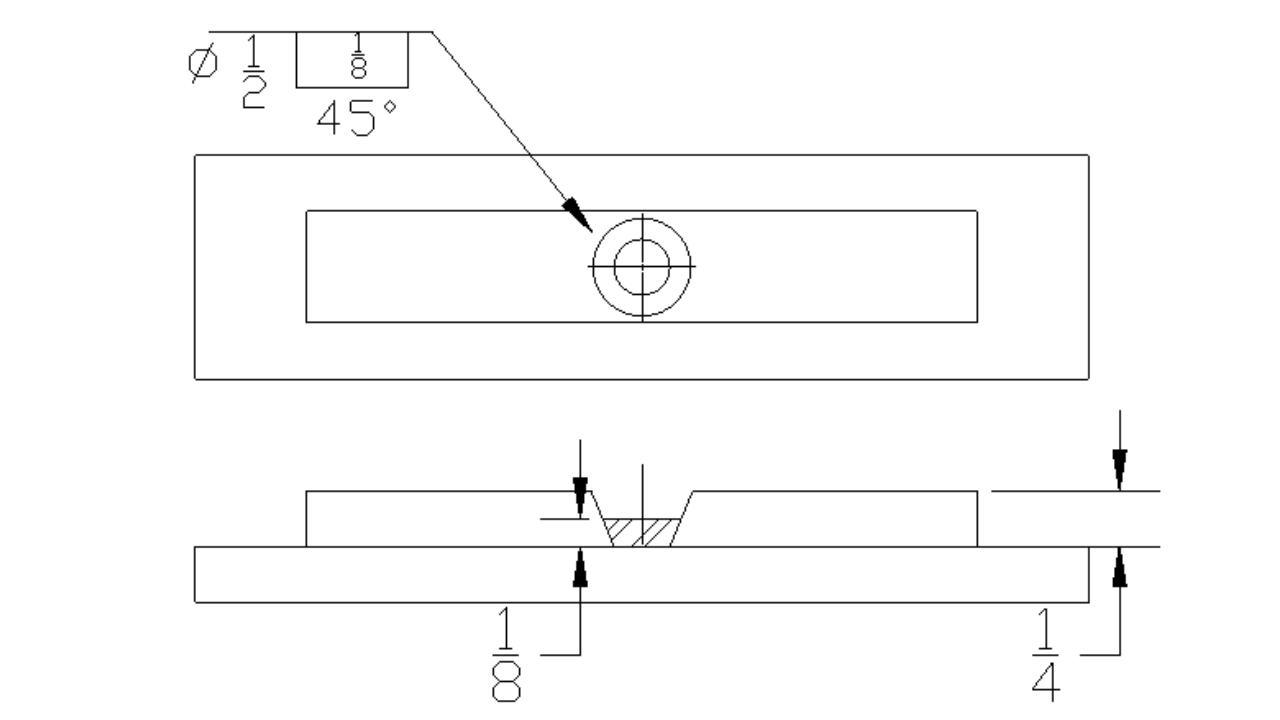

Plug welds are a round weld that is made inside of an existing hole most commonly in one piece of metal, welding that piece to another member. The plug weld symbol is a rectangle with a diameter symbol placed to the left of the symbol as well as the number associated with that diameter.

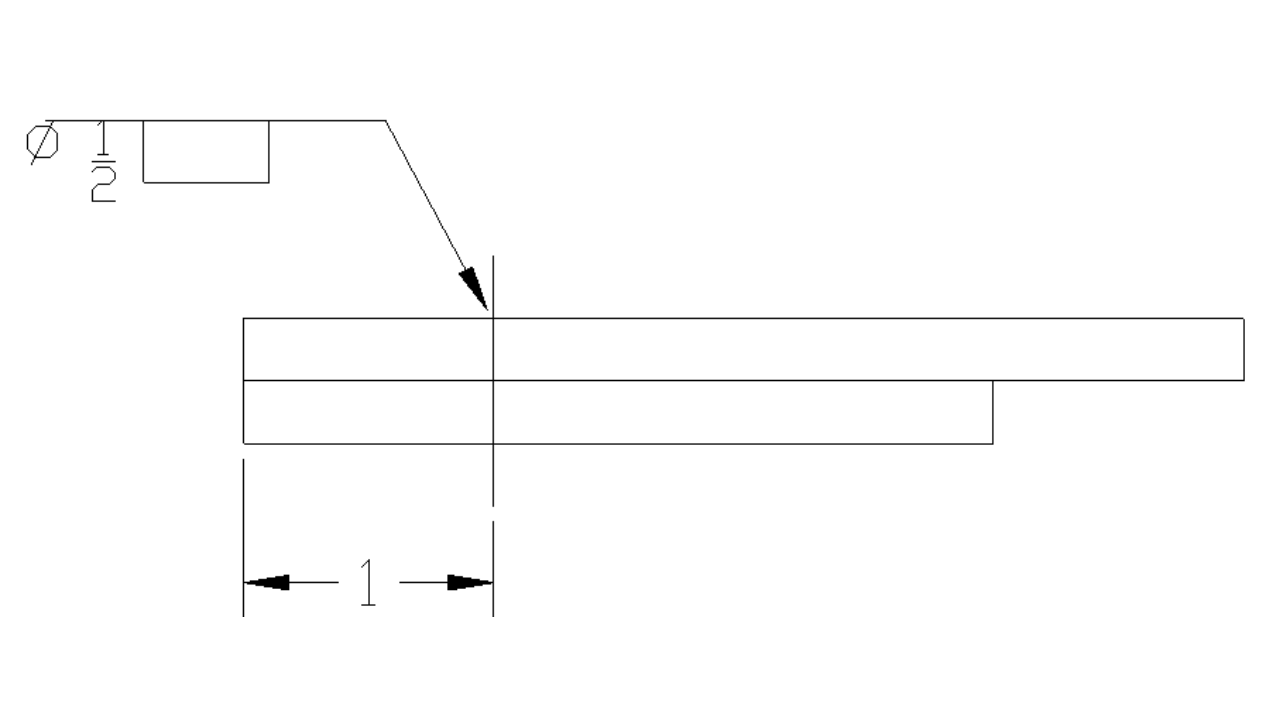

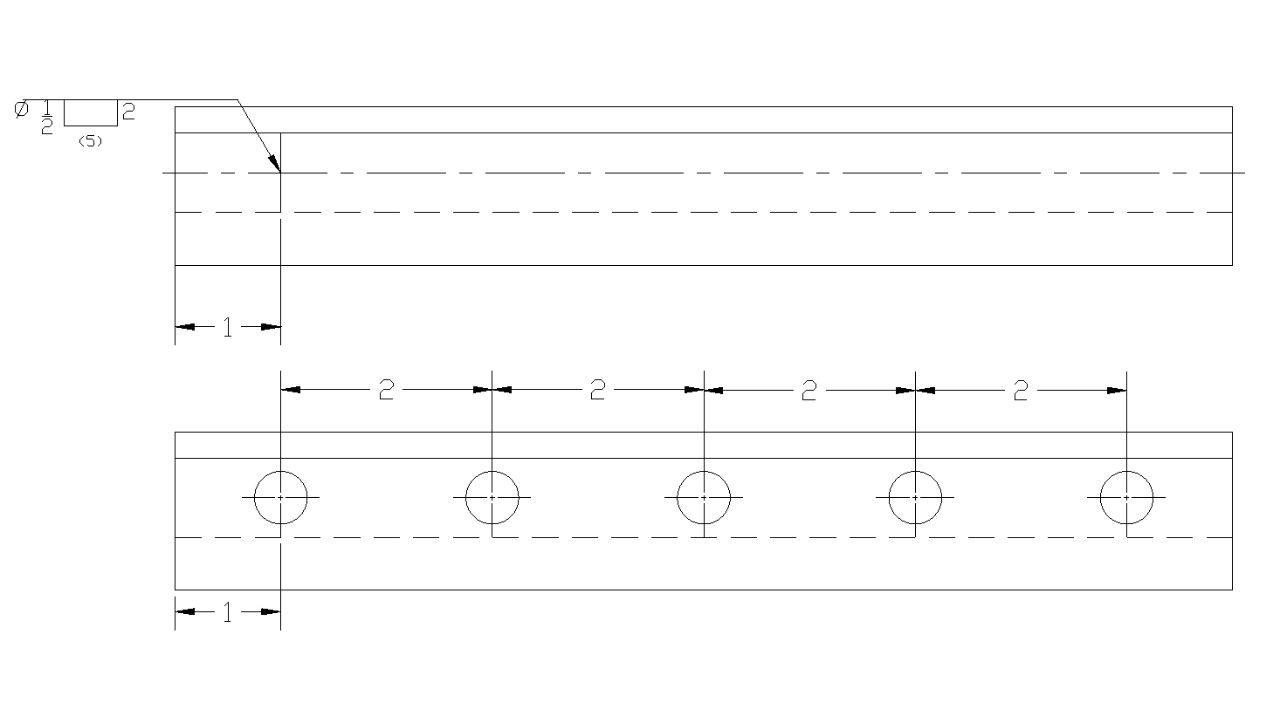

Some drawings will not indicate the hole in the print so the use of dimensions come in to play when locating where a plug weld will be executed. The location will be indicated by a centerline through the part.

Above is indicating a ½” plug weld offset 1” from the edge to the center of the weld.

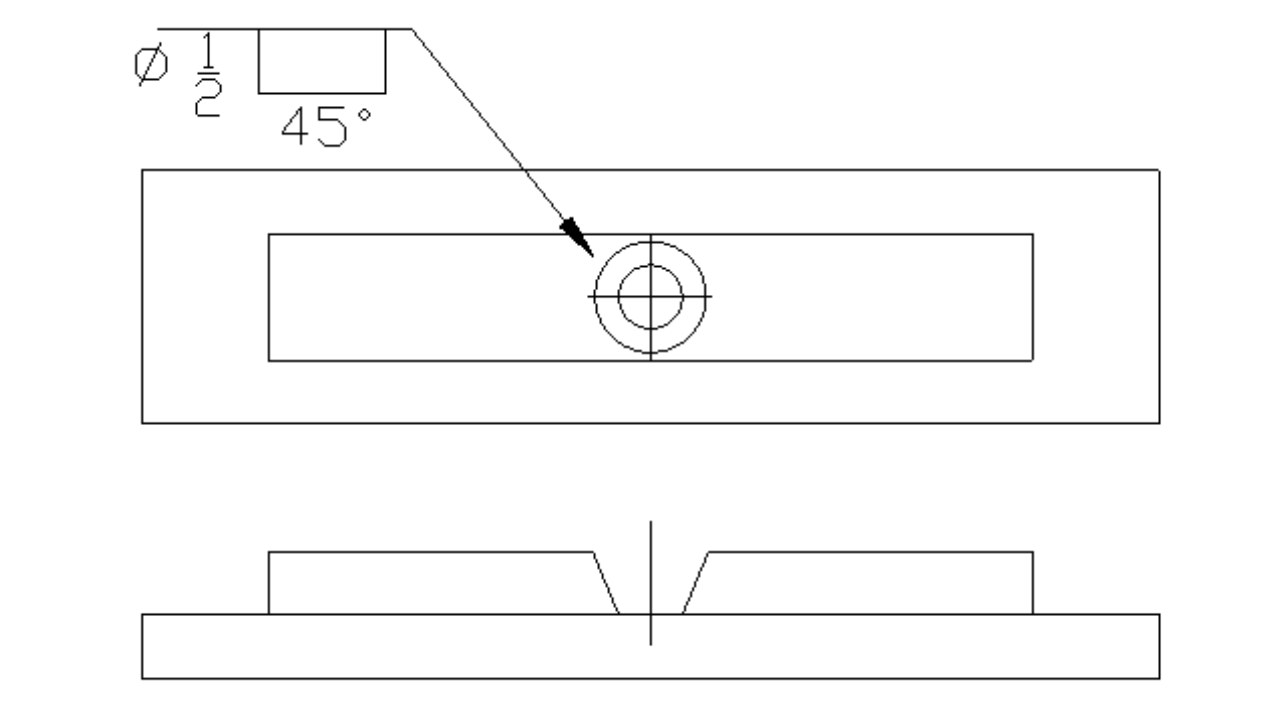

Some plug welds may include a countersink of the hole of the plug weld. This is called the included angle of countersink. This angle is shown below the rectangle of the symbol itself or if the plug weld is to be on the other side it will be placed above the weld symbol. When figuring sizing of the hole remember that the diameter will be the narrow of the hole at the base of the weld.

Without a countersink included it will be necessary to follow shop standards and procedures to dictate what this needs to be, if any angle. Most shops have a procedure in place for tasks that will be done often. If it is needed it may be listed on a welding procedure for the plug welds that are being completed.

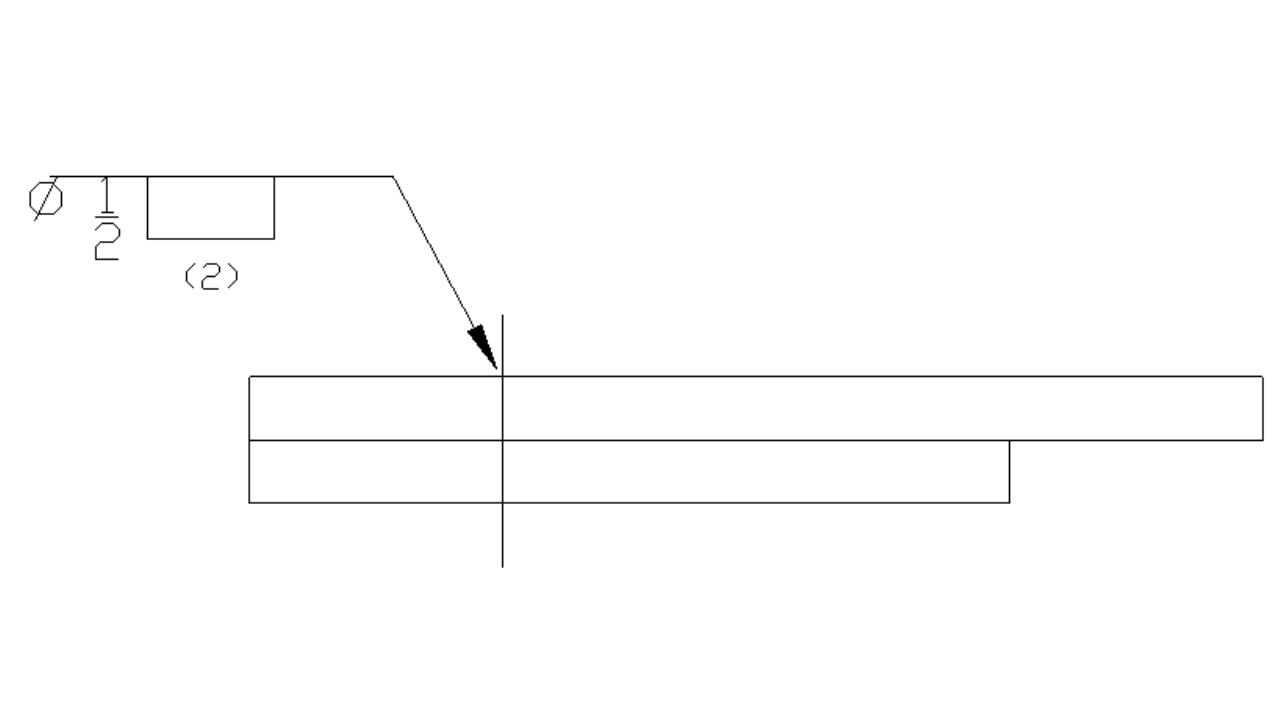

If a number of plug welds are needed there will be yet another element added to the symbol. This will be a number that is surrounded in parentheses, such as (6) for example.

When applying a plug weld it is important to know the depth of fill that is required. If the plug weld should fill the hole provided then the symbol will be left empty.

This means there will be no dimension inside of the rectangle. If the hole should be filled only so much then this will be placed inside of the rectangle.

This dimension will be in a fraction and indicates the amount in inches the hole will be filled, not the necessarily how much the hole will be filled.

Another element that can be added to this weld symbol may be the pitch (spacing) for multiple welds. This is located to the right of the symbol and is a number representing the center to center spacing for weld location.

Plug welds may have a contour symbol which will be added below the symbol or countersink angle if on the arrow side and above if it is on the other side of the reference line.

There are many types of contours and finishing designations, these are covered in supplementary welding symbols.

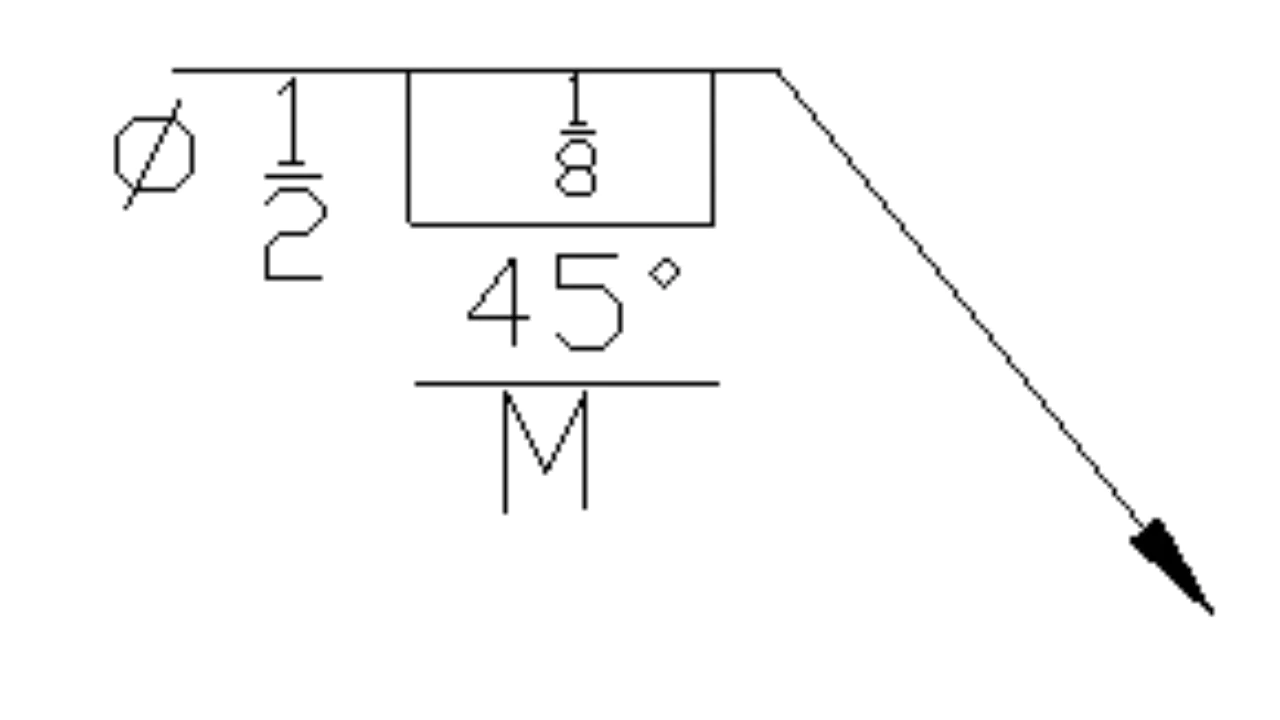

This symbol represents:

- Plug Weld

- Arrow Side

- ½ inch in diameter

- 1/8” amount of fill

- 45 degree included angle of countersink

- Flat contour

- Finished by Machining

Advantages of Plug welding

Following are the advantages of the weld plug that make it different from other welds.

- Speed: It is a fast-speed welding process that makes it more productive in less time frame.

- Strength: It offers more strength that makes it suitable for heavy-duty metals. This weld penetrates the workpiece to a great extent, making it the least unbreakable.

- Versatility: This welding process can be done on different kinds of metals including aluminum, stainless steel, and steel. Its application on different metals makes it versatile.

- Clean and Safe: The fact that the metal needs very little cleaning after completion makes it a very clean process. This weld produces very fewer heat fumes and smoke because of no more heating. It makes it a clean and safe process than many others.

- Economical: This welding doesn’t require much electricity and materials to be used making it a cheap process.

- Easy-to-Learn: This welding method isn’t intricate and can be learned easily.

- Portable: The plug weld material is easy to have in difficult-to-reach places making it easily portable.

Disadvantages of Plug welding

The primary disadvantages associated with plug welding relate to poor quality welds should the process be applied incorrectly.

This includes poorly filled joints, gaps between the welded materials that create a weaker bond, poorly sealed seams due to using too small a rod, weak joins from using a rod that is too large, using too much filler material, or applying inadequate pressure.

However, if the weld is completed correctly, it is a good process that is used for applications including many among automotive enthusiasts.

Uses and Applications of Plug Welding

Plug welding has a range of uses and applications. Able to join dissimilar metals, this type of weld is used for welding sheets of metal as well as for welding a rod inside a pipe or to weld exhaust pipes onto vehicles.

Widely used in the automotive industry, plug welding is also used to install new floors into old vehicles, using small holes drilled around the edge of the new floor pan.

Often used to replace spot welds, plug welding was used by hot rod enthusiasts in the 1960s, who removed the original spot welds in their wheel hubs before reversing the hubs and reattaching them with plug welds. This created deep dished wheels that were then painted or chrome plated.

Plug welding is also used for construction projects where it is used to attach metal beams and support bars.

Plug welds are also used where access is difficult for spot welders, acting as a replacement technique where spot welding is not possible.